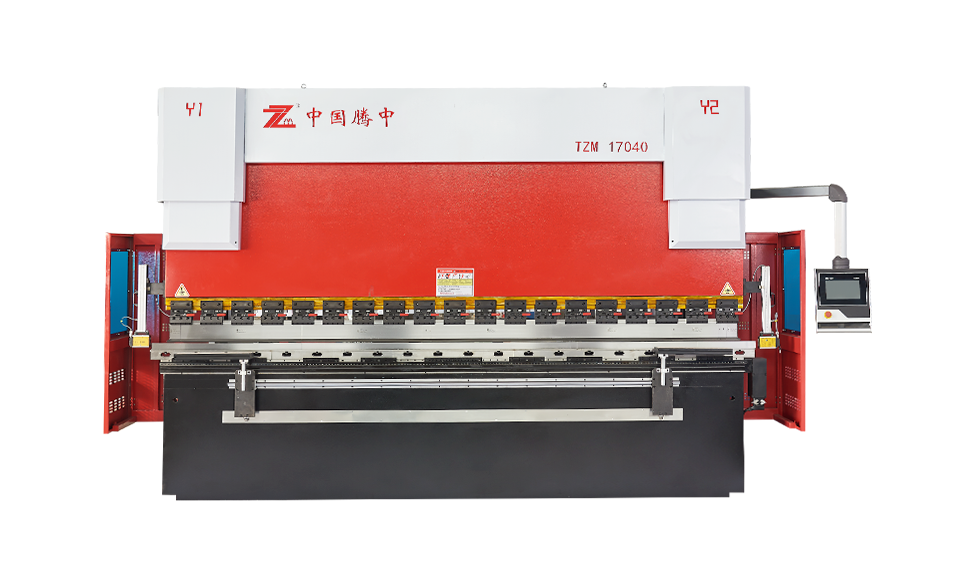

Press brake is a mechanical equipment used to bend metal sheets, pipes, etc. It consists of a pressure system and a bending mold, which achieves processing purposes by applying pressure to the workpiece and utilizing the bending function of the mold. Press brakes are widely used in the metal processing industry and can be used to make parts and components of various shapes, such as boxes, pipes, angle steel, etc. According to different workpieces and processing requirements, bending machines can have different types and specifications, including manual Press brake, hydraulic Press brake, CNC Press brake, etc. Bending machines can be used to process metal plates and pipes of various shapes, including flat plates, curved plates, angle steel, pipes, etc., and can meet the processing needs of different workpieces. Modern bending machines use CNC technology to accurately control processing parameters, ensure processing size and shape accuracy, and improve product quality. It is suitable for processing metal materials of different thicknesses and materials, such as steel plates, aluminum plates, stainless steel plates, etc., and has strong processing adaptability. The operation is relatively simple, and trained operators can master the operation skills and produce quickly.

-

Reduce noise

Reduce noise

A new generation of oil-electric hybrid technology, energy saving and emission reduction, high efficiency and low heat, and greatly reduces working noise; Silent when waiting for fast speed (about 25 dB), low noise when bending and returning (the pressure in the hydraulic system is controlled by the main servo)

View products

View products

-

Power saving

Power saving

Servo motor drives oil pump forward and backward rotation. Flow and pressure are automatically controlled by oil pump and servo motor without overflow control. Zero power is consumed during interprocess waiting. The power consumption of the motor is determined by the load. Long-term

View products

View products

-

High performance

High performance

The outer surface of the machine is coated with two coats of paint at least 60 microns thick to withstand weather conditions; Paint drying is done gradually in state of the art ovens over different time and temperature ranges;

View products

View products

-

High precision

High precision

Bending machines with DSP visible laser protection, compliant with EN12622. The beam protects the bender operator's fingers from the danger of squeezing between the punch and the die.

View products

View products

-

Length (L)

Dimension length to be bent.

-

Length (L)

Dimension length to be bent.

-

Length (L)

Dimension length to be bent.

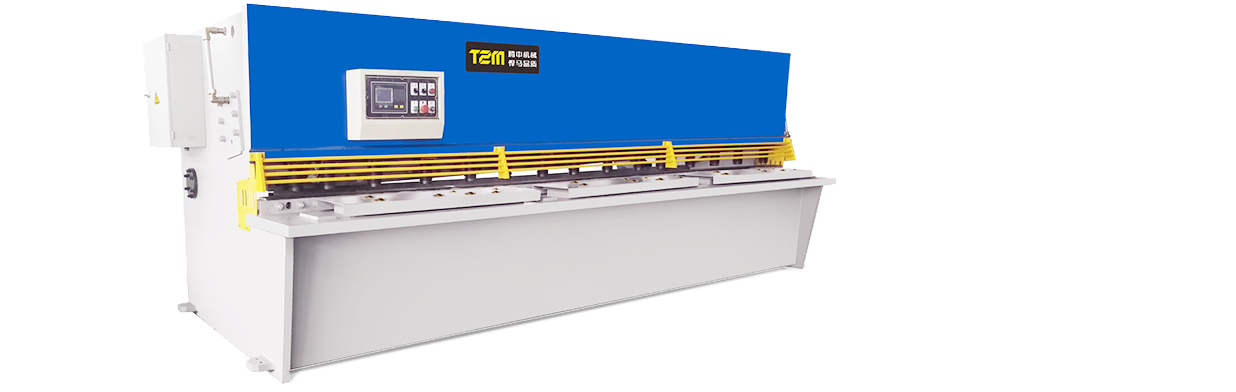

A shearing machine is a mechanical cutting device that uses two sharp blades moving past each other...

-

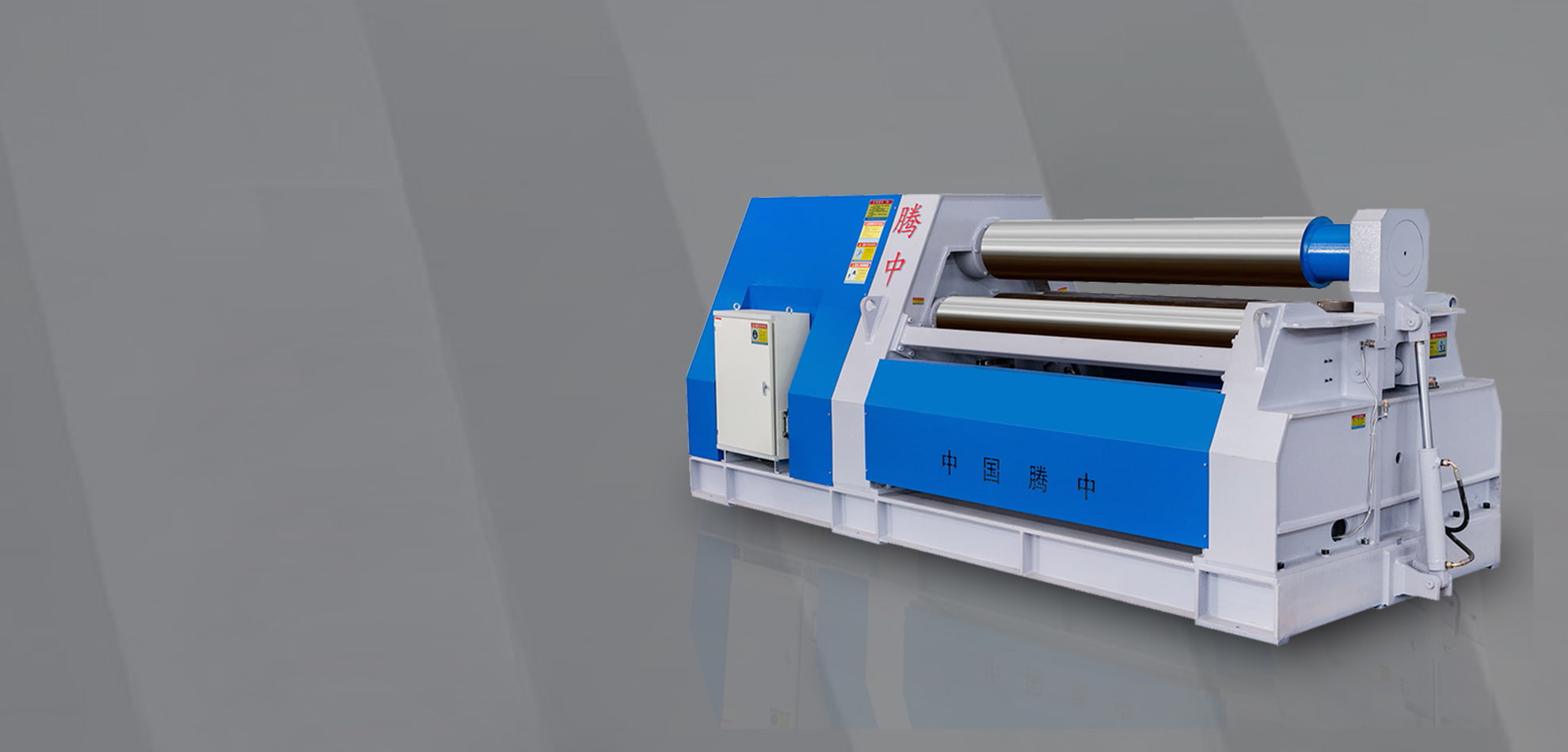

Plate Rolling Machine Guide: Types, Working Principles, Applications, and Buying Tips

Understanding What a Plate Rolling Machine Does A plate rolling machine, also known as a metal plate...

View more

View more

-

Mastering V-Grooving Machines: Precision, Efficiency, and Applications

Introduction to V-Grooving Machines V-grooving machine is specialized cutting tools designed to crea...

View more

View more

-

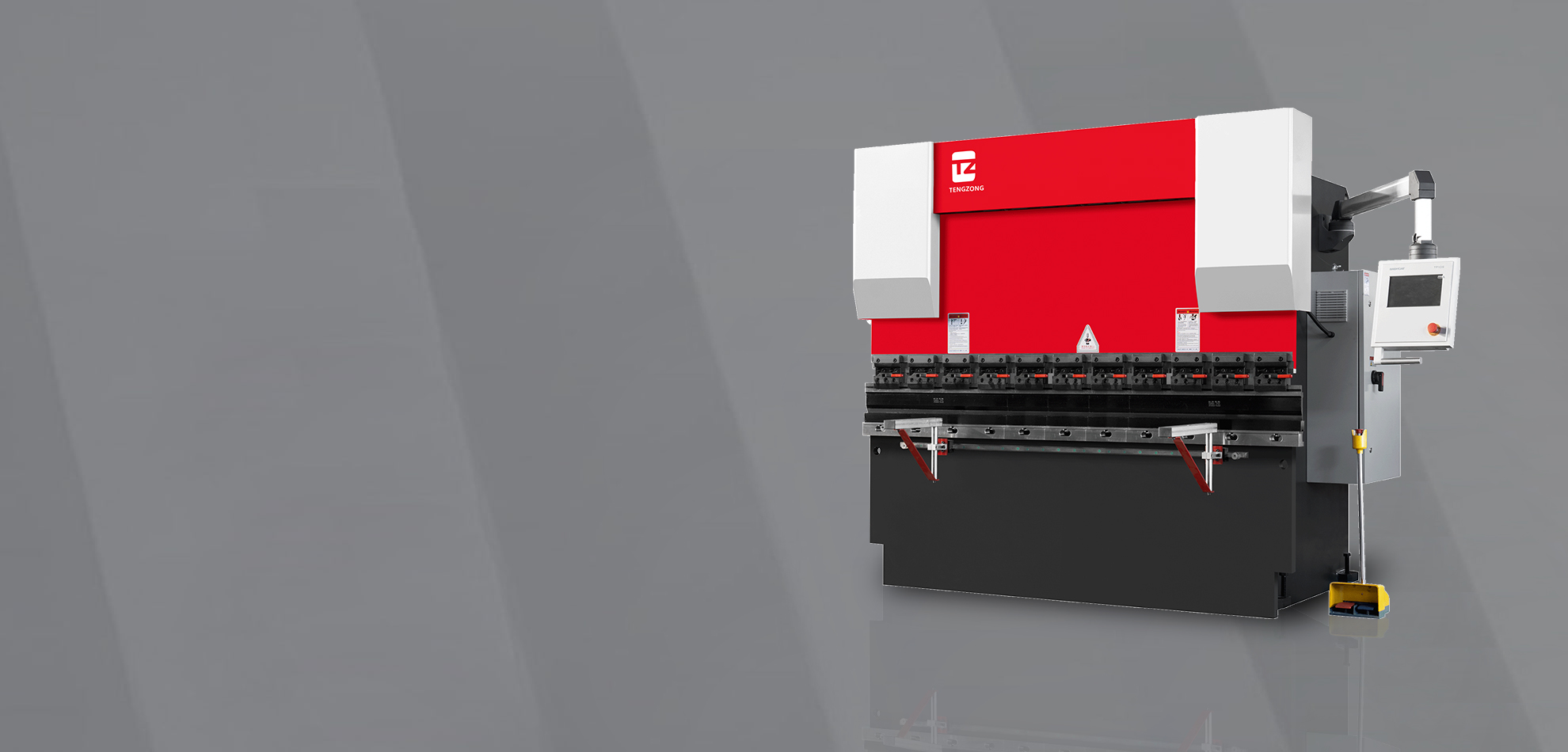

Maximizing Efficiency and Precision with Press Brake Machines: Practical Guide

Understanding Press Brake Machines A press brake machine is an essential tool in sheet metal fabrica...

View more

View more

-

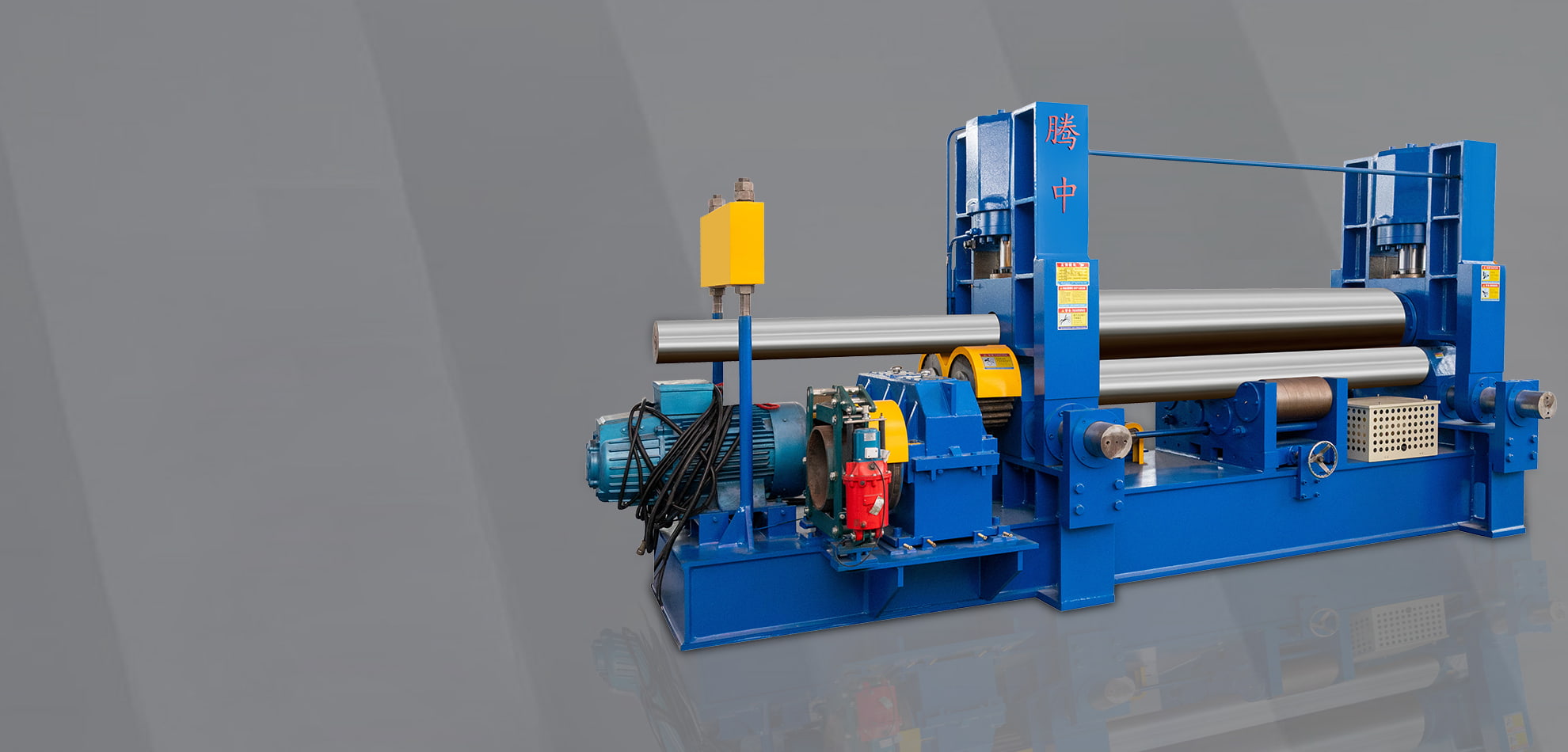

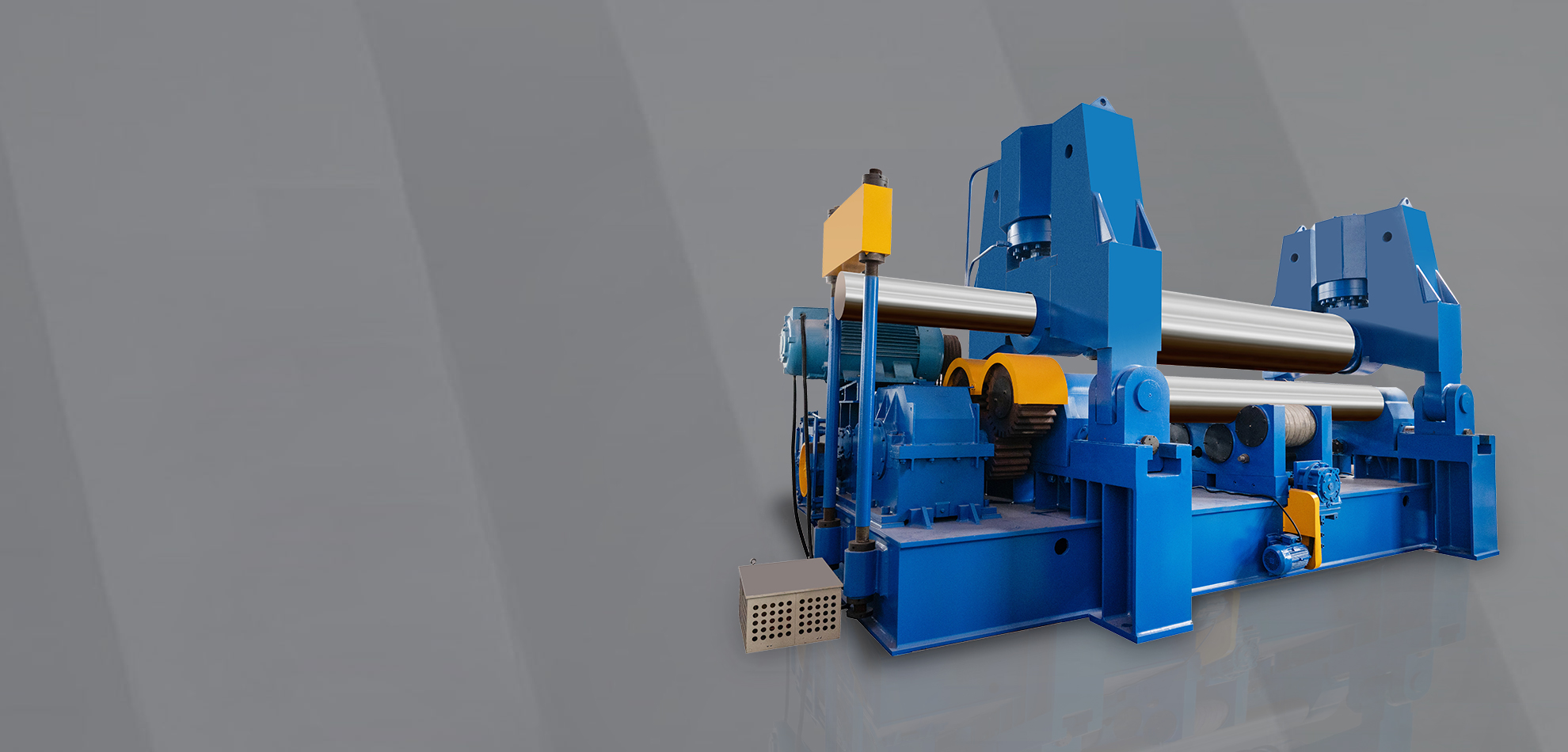

4 Roller Rolling Machine: Comprehensive Guide to Selection, Operation & Maintenance

What Is a 4 Roller Rolling Machine? A 4 roller rolling machine — also called a four‑roller plate ben...

View more

View more

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى