What is the precision and accuracy of CNC 4 roller Plate rolling machine during the rolling process?

The precision and accuracy of a CNC 4-roller plate rolling machine during the rolling process are among its most critical performance metrics, and they can vary depending on several factors, including the machine’s design, quality of the components, and the control system in place. Here’s an overview of what to expect in terms of precision and accuracy:

Tight Tolerances:

Dimensional Accuracy: CNC 4-roller machines can achieve tight tolerances, typically in the range of ±0.1 to ±0.5 mm depending on the material, thickness, and the complexity of the rolled product. For high-precision applications, this level of accuracy ensures that the final product meets design specifications.

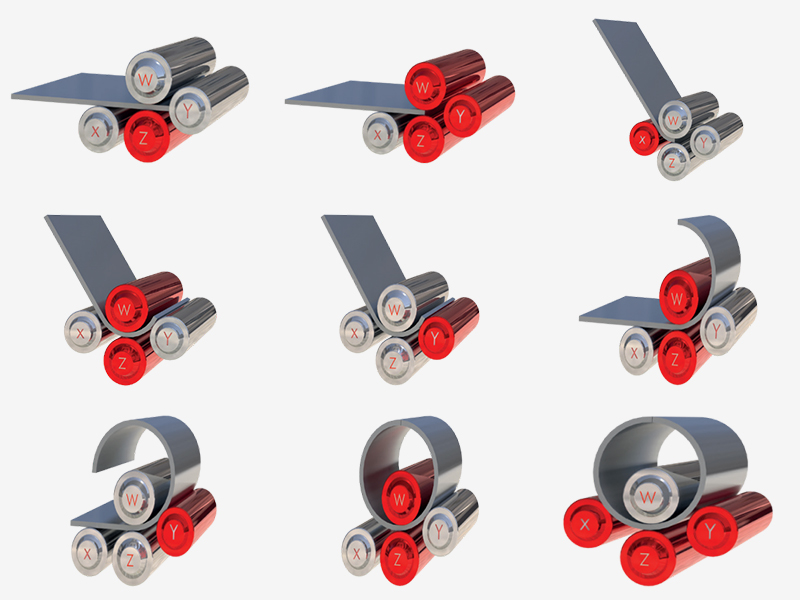

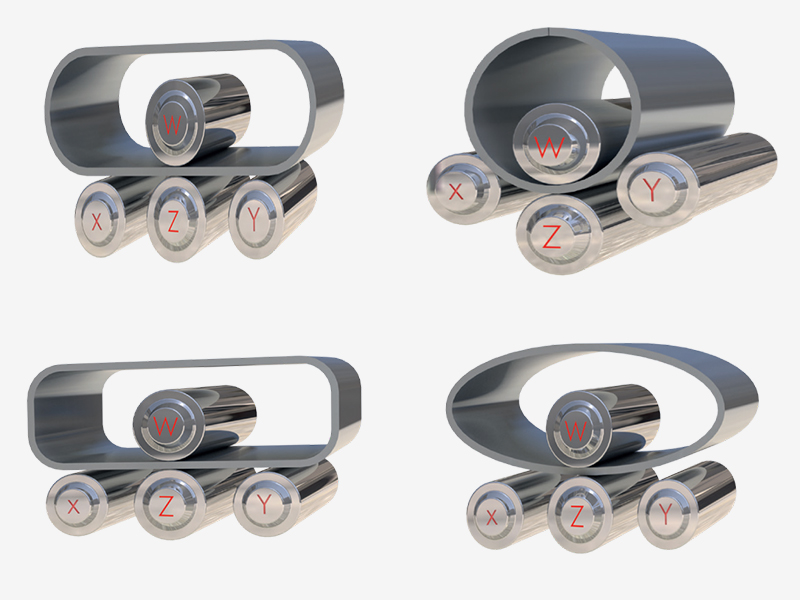

Pre-bending Precision: One of the key advantages of a 4-roller system is its ability to pre-bend the plate with greater precision than 3-roller machines. The pre-bending is performed so that the straight edge of the plate is minimized, improving the overall accuracy of the bend.

Consistent Rolling Radius:

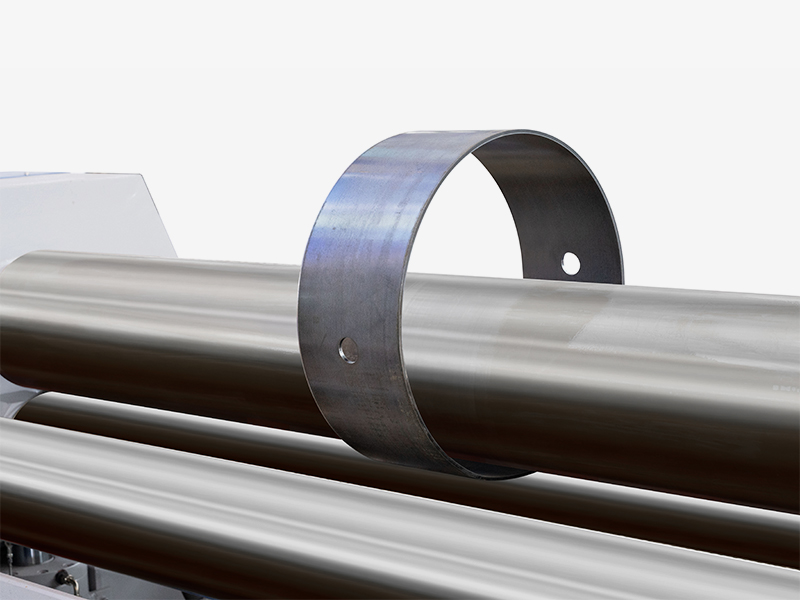

Repeatability: CNC systems control the rolling process with high precision, ensuring that the rolling radius remains consistent throughout the process. For applications like large-diameter cylinders, the machine can roll plates with a consistent radius even across longer lengths or thicker materials.

Accuracy in Cylindricity: The 4-roller configuration allows for more control over the plate during the rolling process, improving the final shape's uniformity, especially in terms of the cylinder's roundness and smoothness.

Precise Control of Material Deformation:

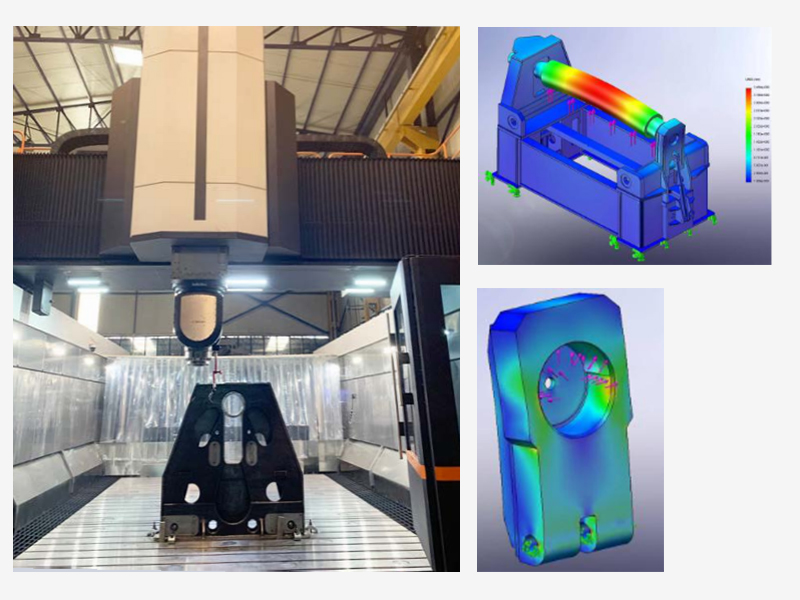

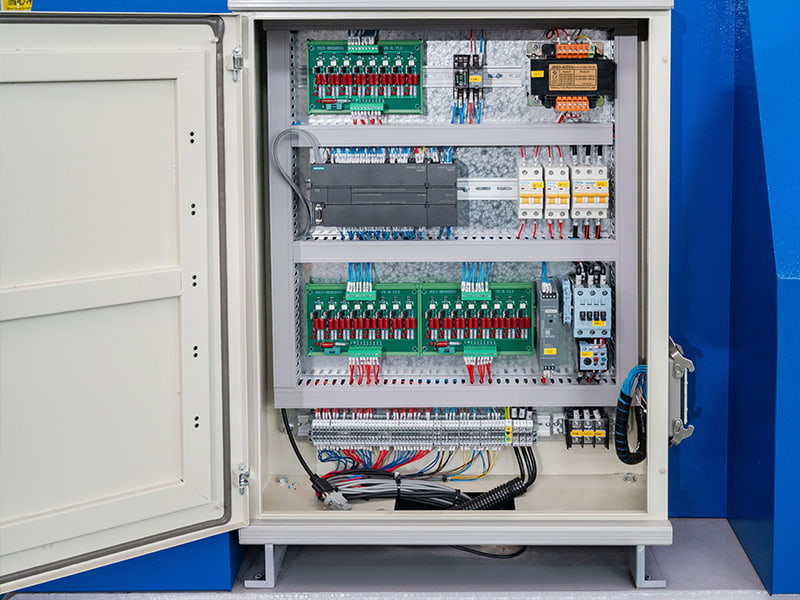

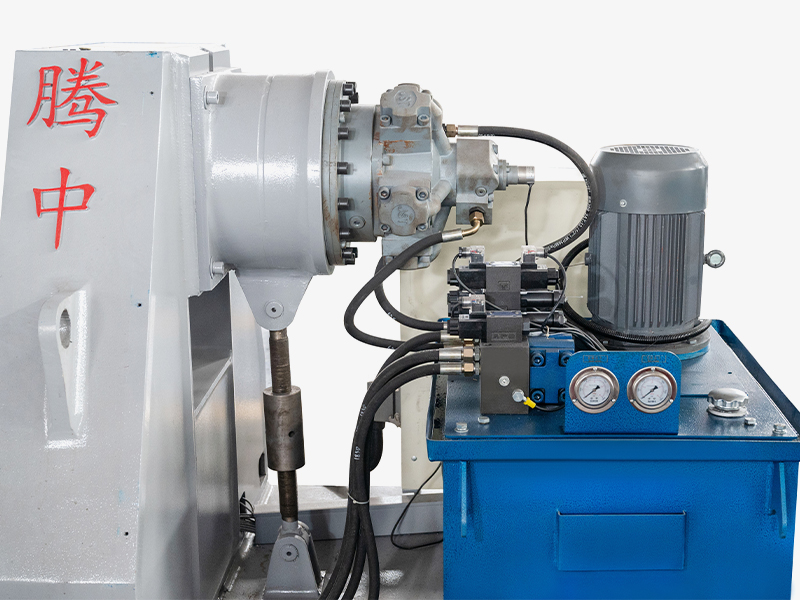

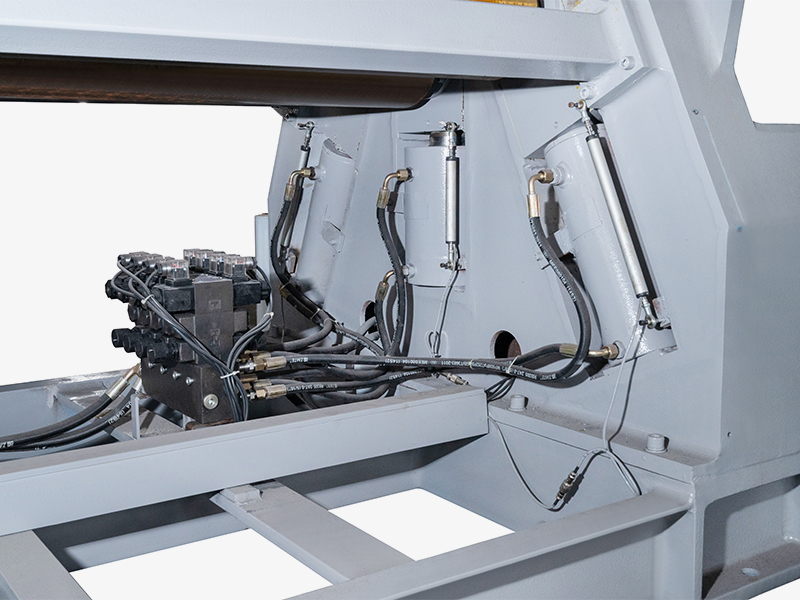

Servo-Driven Rolls: Many CNC 4-roller machines use servo-driven rolls to control the plate’s position with high accuracy, enabling precise adjustments during the rolling process. The CNC system automatically adjusts parameters like pressure, speed, and position, ensuring consistent deformation across the plate.

Real-Time Feedback: These machines are typically equipped with real-time monitoring and feedback systems, allowing for dynamic adjustments during the rolling process. This reduces the chances of errors and ensures high-precision results.

Edge Quality and Bending Consistency:

Edge Alignment: Since the CNC system controls the plate's position and movement, edge quality is improved. Plates are aligned precisely, ensuring straight and accurate edges during the rolling process.

Pre-bending and Clamping: The clamping point in the 4-roller machine typically falls right at the plate’s edge, ensuring minimal straight edge sections after bending and improving overall bending consistency.

Material-Specific Accuracy:

The accuracy can vary slightly based on the type of material being processed (e.g., aluminum, steel, titanium). Softer materials might be easier to roll with precision, while harder materials may require additional fine-tuning of the parameters.

CNC Control Precision:

Digital Precision: With modern CNC systems, the precision in controlling the rolling process is extremely high, often capable of achieving sub-millimeter accuracy. The CNC software ensures that all movements and rolling sequences are carefully controlled, optimizing the bending and rolling accuracy based on the programmed specifications.

The CNC 4-roller plate rolling machine is highly precise and accurate, particularly in applications that require tight tolerances, consistent radii, and minimal straight edge sections. It outperforms traditional 3-roller systems by offering superior pre-bending capabilities and automated, real-time adjustments, ensuring high repeatability and precision in the rolling process.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى

High-precision plate rolling

High-precision plate rolling