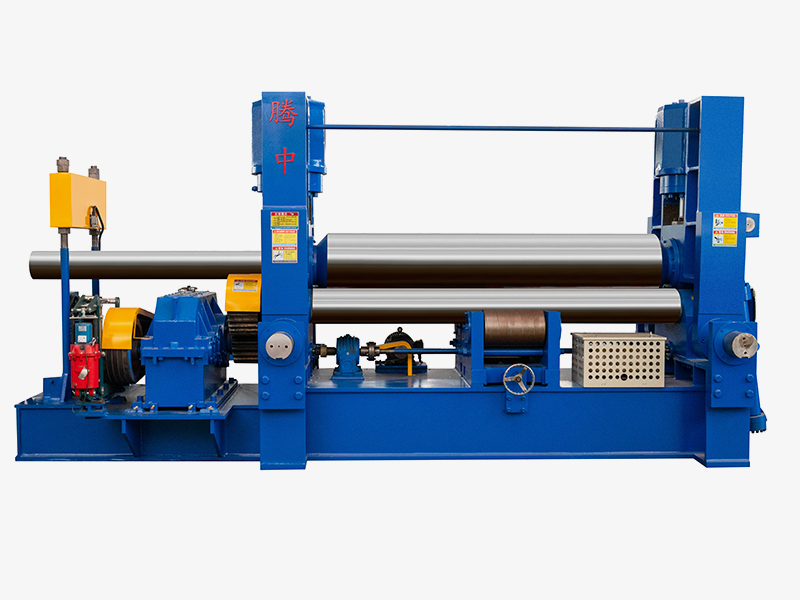

Hydraulic 3 Roller Rolling Machine

1. This type of plate winding machine has the function of plate end pre-bending, and the remaining straight edge of pre-bending is less than 2.5 times the plate thickness.

1. This type of plate winding machine has the function of plate end pre-bending, and the remaining straight edge of pre-bending is less than 2.5 times the plate thickness.

2. Adopt EPS automatic electronic leveling technology, real-time monitoring, and real-time adjustment, automatically adjust the upper roller levelness, and keep the upper and lower rollers parallel.

2. Adopt EPS automatic electronic leveling technology, real-time monitoring, and real-time adjustment, automatically adjust the upper roller levelness, and keep the upper and lower rollers parallel.

3. The unique post-bending process of this type of plate rolling machine can realize pre-bending at the end, continuous bending without a back corner, and the bending process is a fully digital display.

3. The unique post-bending process of this type of plate rolling machine can realize pre-bending at the end, continuous bending without a back corner, and the bending process is a fully digital display.

4. Large-size LCD touchscreen digital display, man-machine dialogue control interface, efficient and intuitive operation.

4. Large-size LCD touchscreen digital display, man-machine dialogue control interface, efficient and intuitive operation.

5. The fixed disturbance compensation of the upper roller is combined with the variable disturbance compensation of the lower roller to effectively overcome the influence of disturbance deformation and improve the straightness of the product.

5. The fixed disturbance compensation of the upper roller is combined with the variable disturbance compensation of the lower roller to effectively overcome the influence of disturbance deformation and improve the straightness of the product.

6. With a variety of overload and safety protection functions, interlocking, automatic fault alarms and prompts, can effectively prevent misoperation, and protect the safety of equipment and operators.

6. With a variety of overload and safety protection functions, interlocking, automatic fault alarms and prompts, can effectively prevent misoperation, and protect the safety of equipment and operators.

7. High strength overall welded chassis and bracket, strong structure, durable. The chassis adopts a frame structure, high torsion section coefficient, fewer anchor bolts, and convenient installation and debugging.

7. High strength overall welded chassis and bracket, strong structure, durable. The chassis adopts a frame structure, high torsion section coefficient, fewer anchor bolts, and convenient installation and debugging.

8. The whole frame is annealed to eliminate stress and never deform.

8. The whole frame is annealed to eliminate stress and never deform.

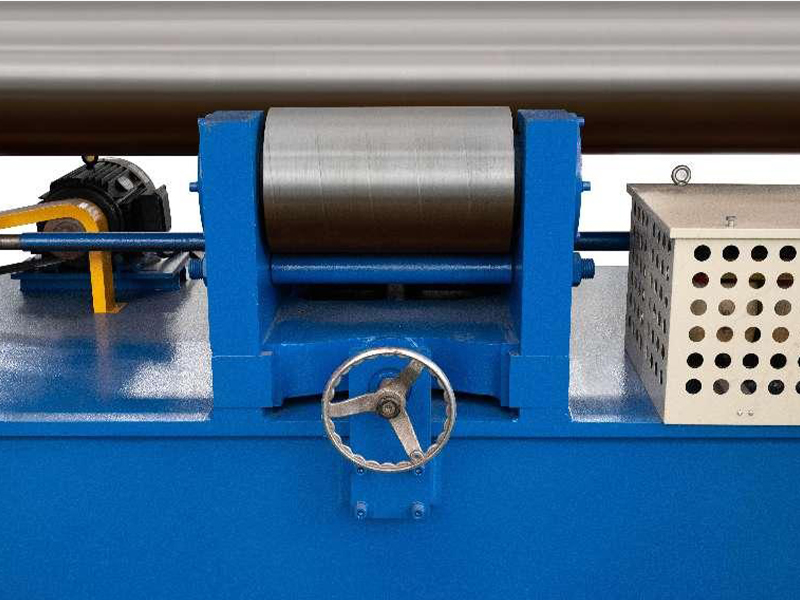

9. The work roller is 42crmo integral forging, after the tempering, quenching hardening process. The roller material is 45# steel, tempered treatment, hardness HB190~220.

9. The work roller is 42crmo integral forging, after the tempering, quenching hardening process. The roller material is 45# steel, tempered treatment, hardness HB190~220.

10. Hydraulic valve selection superposition valve series, pipe layout is simple, easy to maintain and debug.

10. Hydraulic valve selection superposition valve series, pipe layout is simple, easy to maintain and debug.

|

Roller mounting device The upper roller device is composed of an upper roller, main oil cylinder, upper roller bearing seat, and double row aligning bearing. |

|

|

Lower roller and horizontal moving device The lower roller device is composed of a lower roller, lower roller bearing seat, lower roller sliding bearing, lower roller input gear, etc. |

|

|

Support roller device The idler device is composed of an idler combination, oblique wedge mechanism, and spiral mechanism. |

|

|

Main drive system The main drive system is composed of the main motor, reducer, output gear, etc. |

|

|

Tipping device The tipping device is composed of a pin shaft, a ram, a tipping hydraulic cylinder, a support, etc. ◆ Balancing device: The balancing device consists of two pull rods and a balancing beam. ◆ Rack: Fixed and overturned frame for welding parts, after welding vibration aging to remove stress treatment. The frame is used to mount the hydraulic cylinder and move the upper roll components horizontally. ◆ Base plate: The chassis is a box welded structure, an annealing treatment. Used to install components. |

|

|

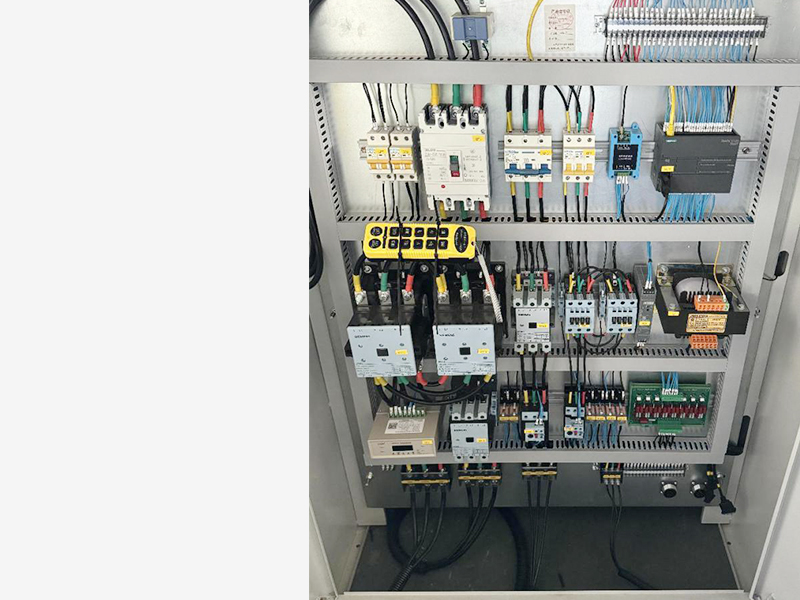

Electrical control system The electrical control system consists of an electrical control cabinet, an operation table, and a hand-held button box. |

|

|

Numerical control system The CNC system has the functions of real-time monitoring, in-place control, and short electrical memory in the rolling process. |

|

|

Wireless remote controller Control the plate rolling machine by handheld remote control, easy to operate. |

|

|

Tipping device The tipping device is composed of a pin, a ram, a tipping hydraulic cylinder, a support, etc. The tipping hydraulic cylinder drives the tipping frame to tip over or reset. When the tipping frame tips over, it is convenient to take out the product along the tipping end. |

|

-

Dec 24,2025 _ShuaibiaoIntroduction to V-Grooving Machines V-grooving machine is specialized tools designed to create precise V-shaped grooves on sheet materials such as aluminum, steel, and composite panels. They are widel...Read More

-

Dec 19,2025 _ShuaibiaoUnderstanding the Role of a Plate Rolling Machine A plate rolling machine is designed to bend flat metal plates into cylindrical, conical, or curved shapes with controlled accuracy. It is commonly use...Read More

-

Dec 12,2025 _ShuaibiaoUnderstanding the Foundation: Tonnage and Material Before selecting a single tool, you must calculate the required bending tonnage. Exceeding the press brake's capacity or the tool's rating is danger...Read More

What are the typical applications of 3 roller hydraulic plate rolling machine in industries such as shipbuilding, aviation or steel structure?

3 roller hydraulic plate rolling machine is widely used across various industries due to their efficiency and precision in bending and rolling metal plates. Here are some typical applications in key industries like shipbuilding, aviation, and steel structures:

Shipbuilding

Hull Construction: The machine is used to roll large steel plates into cylindrical shapes for ship hulls, ensuring structural integrity and optimal hydrodynamics.

Decks and Bulkheads: Plates are bent for constructing decks and bulkheads, which require precise curvature to fit the ship's design.

Tank Construction: Rolling machines help create cylindrical tanks for storing fuel, water, and other liquids on ships.

Aviation

Aircraft Fuselages: The rolling machine is utilized to form the fuselage sections of aircraft, which require specific curvatures for aerodynamic performance.

Wing Structures: Curved components for wings, such as leading and trailing edges, can be produced using a 3 roller hydraulic plate rolling machine.

Aerospace Components: Other parts, such as engine housings and structural frames, benefit from the precision bending capabilities of the machine.

Steel Structure Construction

Structural Beams and Columns: The machine rolls plates to create curved beams and columns used in architectural designs and structures, enhancing aesthetic appeal and structural support.

Bridges and Overpasses: Plate rolling is essential in fabricating components for bridges, including arch sections and other curved structural elements.

Industrial Frameworks: It is used to create curved frames for various industrial applications, including machinery support and building frameworks.

Manufacturing and Fabrication

Storage Tanks: The machine is employed to roll plates for constructing large storage tanks used in various industries, such as oil and gas, chemicals, and water treatment.

Pressure Vessels: Rolling machines are essential in the fabrication of pressure vessels that require precise curvature to withstand high pressures.

Pipes and Tubing: It can be used to roll plates into large diameter pipes and tubes for plumbing, industrial, and agricultural applications.

Decorative and Architectural Applications

Architectural Features: The machine can create curved elements for buildings, such as arches, domes, and decorative facades.

Furniture Design: In the furniture industry, it is used to create rounded metal components for various furniture designs, enhancing aesthetic appeal.

Renewable Energy

Wind Turbine Components: The machine is used to roll plates for the manufacture of components such as towers and blades in wind turbines.

Solar Panel Frames: Rolling machines can also be employed to create curved frames for solar panels, contributing to the renewable energy sector.

The versatility and precision of 3 roller hydraulic plate rolling machine make them indispensable in industries that require accurate bending and shaping of metal plates. Their applications range from heavy-duty structural components in shipbuilding and aviation to aesthetic features in architecture and renewable energy, demonstrating their crucial role in modern manufacturing and construction.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى