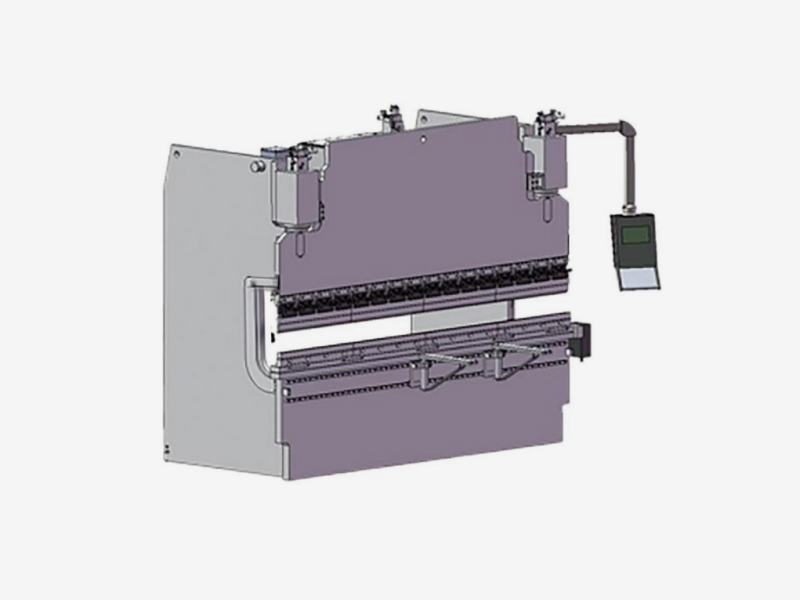

How energy-efficient is the tandem CNC press brake?

The energy efficiency of a tandem CNC press brake depends on several key factors related to the machine’s design, control systems, and usage. While tandem CNC press brakes are generally more efficient than older, traditional hydraulic press brakes, there are still specific considerations that affect their overall energy consumption. Here's a breakdown of what influences the energy efficiency of such machines:

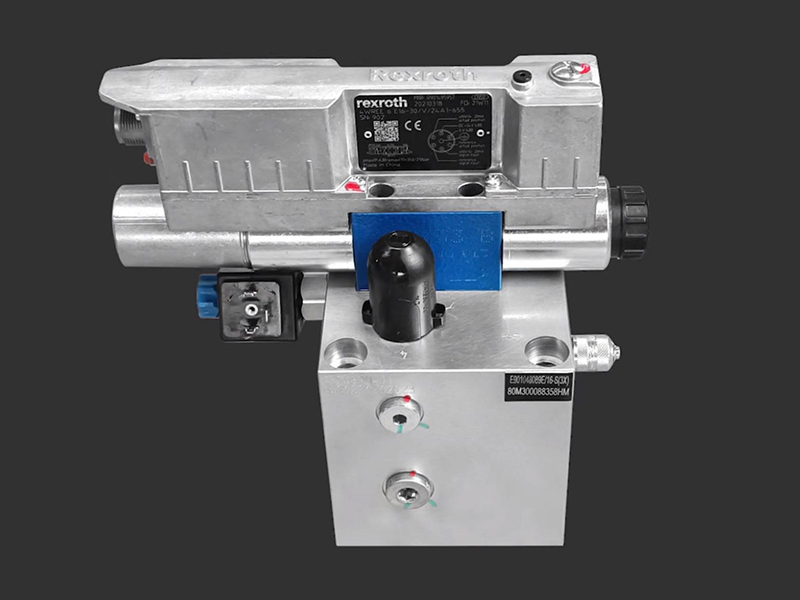

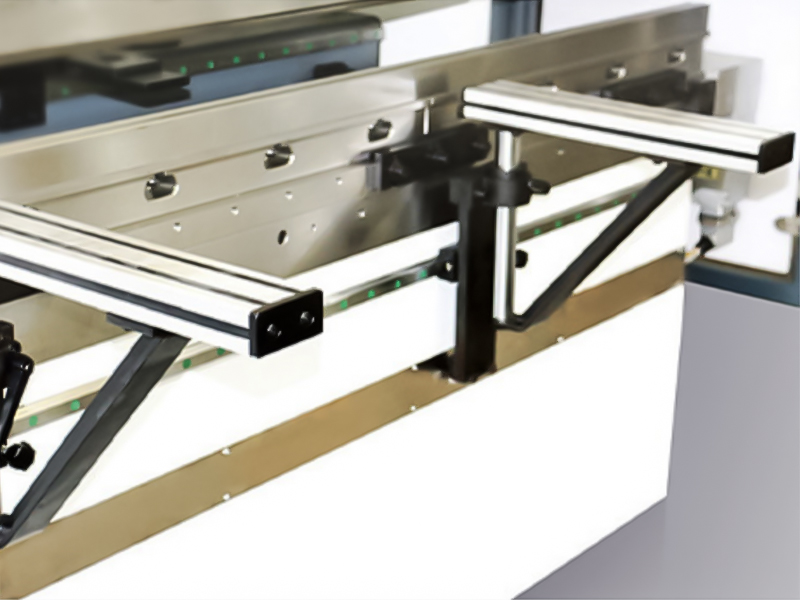

Electro-Hydraulic Servo Systems

Energy Efficiency Advantage: Modern tandem CNC press brakes are often equipped with electro-hydraulic servo systems, which are more energy-efficient compared to traditional hydraulic systems. These systems use energy only when the machine is in motion, rather than maintaining constant hydraulic pressure, which reduces idle power consumption.

Why It’s Efficient: The use of servo motors in tandem systems allows for precise control over hydraulic pressure and reduces energy waste during standby periods. This on-demand approach means that energy is only consumed when necessary.

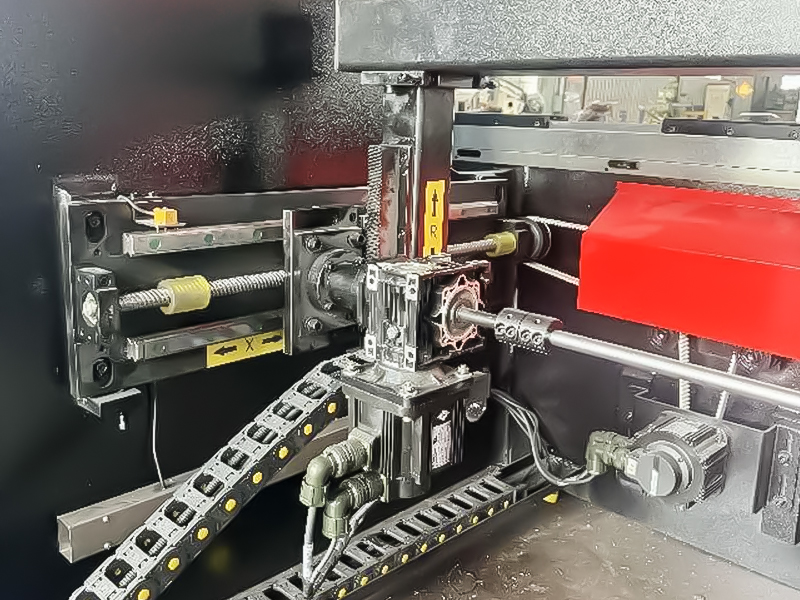

Variable Speed Drives

Energy Efficiency Advantage: Tandem CNC press brakes typically use variable frequency drives (VFDs) or variable speed drives (VSDs), which allow the machine to adjust the speed and torque of the motors based on the specific load requirements.

Why It’s Efficient: By optimizing motor performance and reducing energy usage during low-load operations (e.g., when the machine is idling or moving slowly between tasks), energy consumption is significantly reduced. This results in energy savings, especially in high-production environments.

Reduced Idle Power Consumption

Energy Efficiency Advantage: Many modern press brakes, including tandem models, have systems in place that minimize power usage when the machine is not actively bending. Features like automatic shutdown after periods of inactivity further reduce energy consumption.

Why It’s Efficient: During downtime or breaks between production cycles, the machine consumes minimal power, which improves overall energy efficiency in operations that aren’t constantly running.

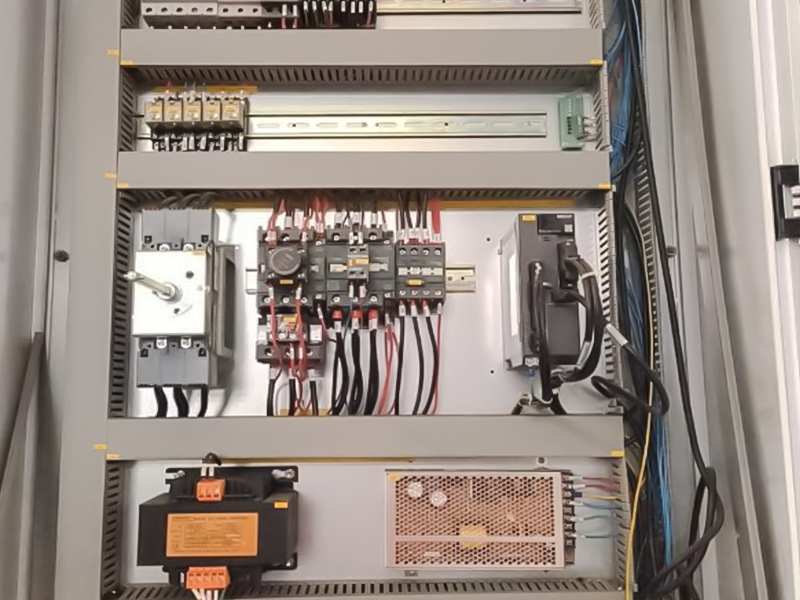

CNC Control Systems

Energy Efficiency Advantage: Advanced CNC control systems contribute to energy efficiency by optimizing the bending process. The CNC system can adjust the press brake's movements and power usage in real time, reducing unnecessary energy expenditure during each operation.

Why It’s Efficient: CNC optimization allows for shorter cycle times and more precise control over the bending process, which translates to lower energy consumption per part produced.

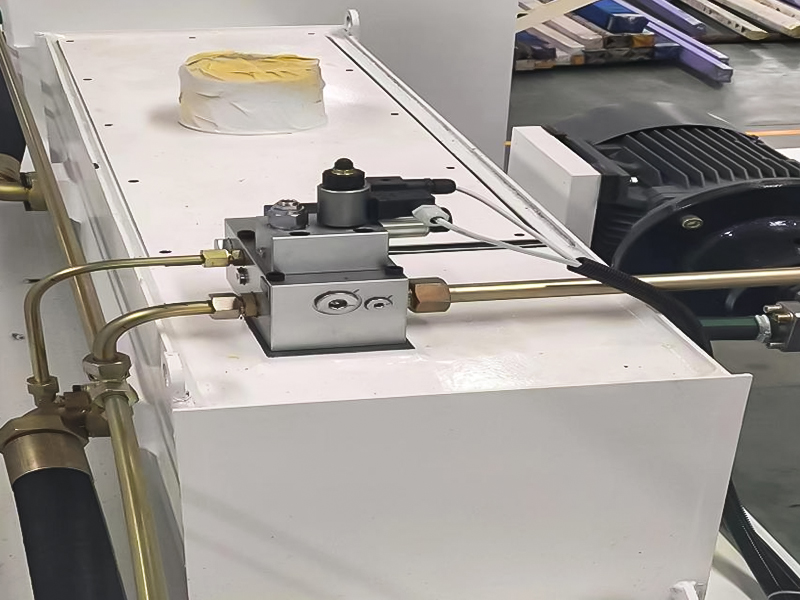

Regenerative Hydraulic Systems

Energy Efficiency Advantage: Some tandem CNC press brakes use regenerative hydraulic systems that recycle energy during operation. These systems can capture excess hydraulic energy generated during the press brake’s return stroke and reuse it, rather than dissipating it as heat.

Why It’s Efficient: By recycling energy, the system requires less power from external sources, lowering the overall energy footprint of the machine.

Energy-Saving Modes

Energy Efficiency Advantage: Many CNC press brakes, especially modern models, come with energy-saving modes or settings that reduce power consumption during idle periods or between tasks.

Why It’s Efficient: These modes allow the machine to enter a low-power state when not actively engaged in bending operations, conserving energy without needing to fully power down.

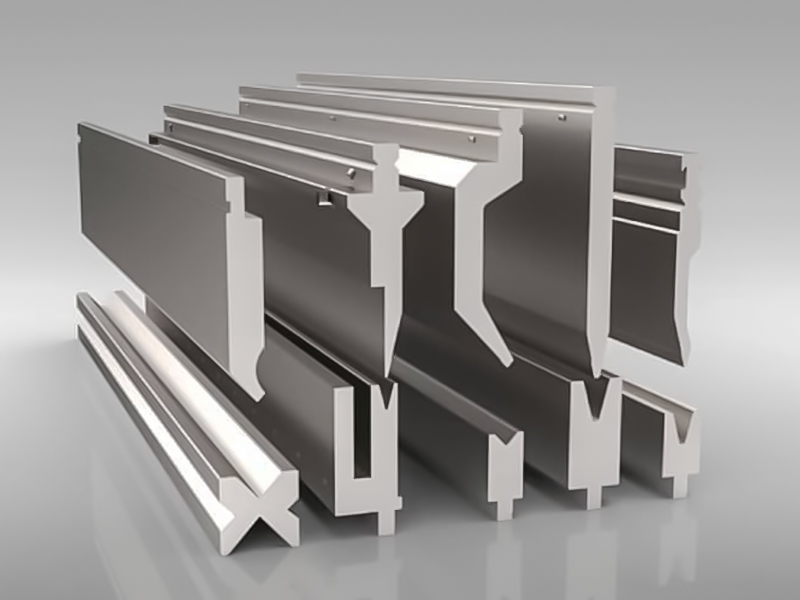

Machine Size and Load Demand

Energy Efficiency Consideration: The size of the machine and the demands of the operation (i.e., the thickness of the material and the complexity of the bends) directly impact energy efficiency. A larger tandem press brake working on thick materials will naturally consume more energy, but if it is used optimally for large-scale production, the energy per part produced can be minimized.

Why It’s Important: Energy efficiency in a tandem CNC press brake is maximized when the machine is used for tasks that take advantage of its high capacity and tandem capabilities. Operating the machine under low load or infrequent use may not be as energy efficient.

Longer Machine Life and Less Wear

Energy Efficiency Consideration: Machines with more energy-efficient systems often have less wear and tear, meaning they operate more efficiently over their lifespan. For example, servo-driven systems experience less mechanical stress, which leads to longer component life and more consistent performance.

Why It’s Efficient: Reduced mechanical wear means that the machine will maintain its energy efficiency longer and require fewer energy-intensive repairs or replacements.

Eco-Friendly Design Choices

Energy Efficiency Advantage: Some manufacturers design their tandem CNC press brakes with eco-friendly features, such as low-energy hydraulic fluids, more efficient cooling systems, and recyclable components.

Why It’s Efficient: These design choices contribute to a lower environmental impact, reducing the overall energy footprint of the machine during both operation and eventual disposal.

Overall Efficiency Summary:

Tandem CNC press brakes are designed to be more energy-efficient than traditional hydraulic press brakes due to the incorporation of servo systems, variable speed drives, and energy-saving features. However, the actual efficiency depends on factors like machine usage, material thickness, and operational settings. When used optimally, tandem press brakes can offer significant energy savings compared to older models, particularly in high-volume, large-scale production environments.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى