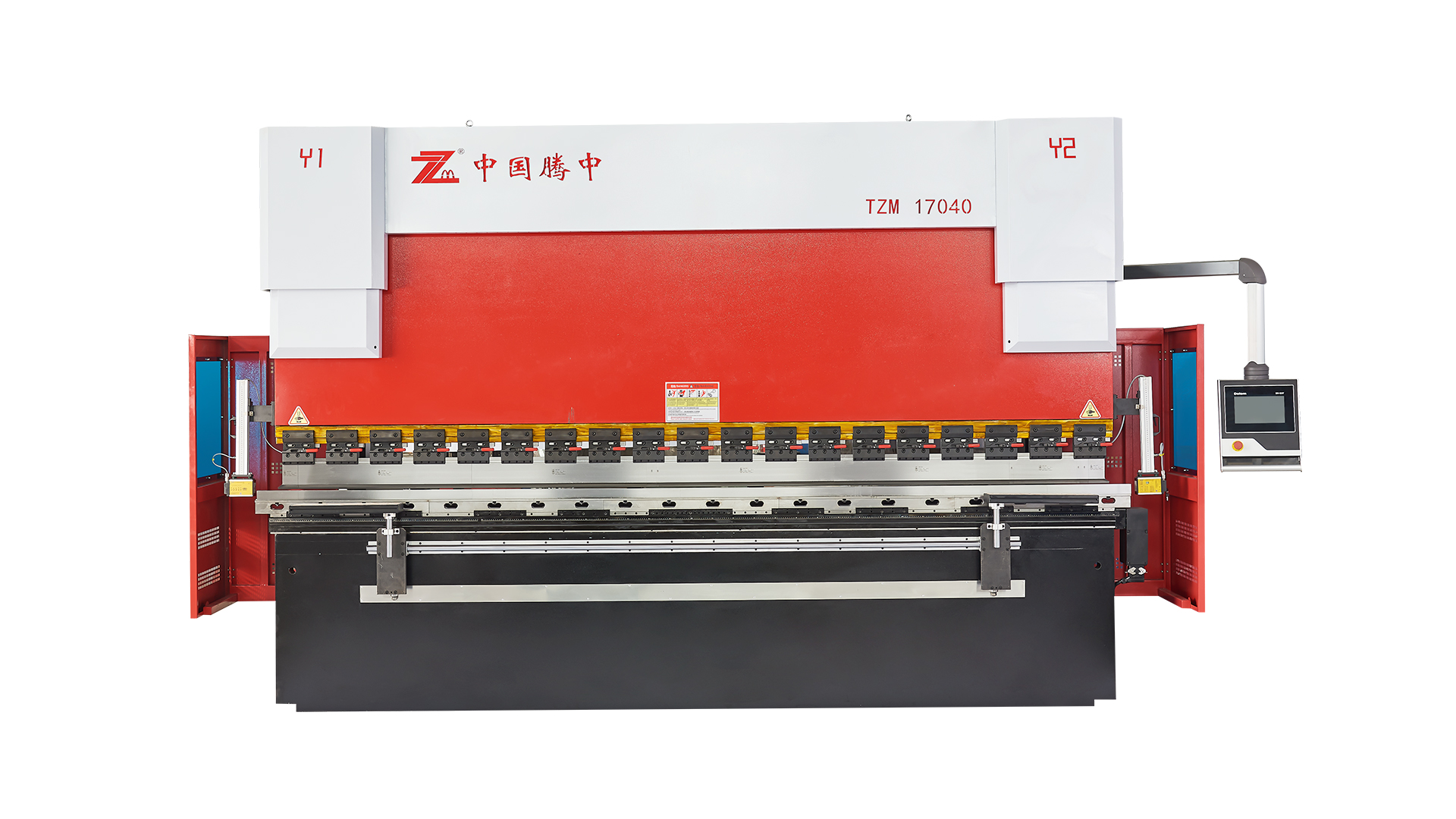

Premium CNC Servo Press Brake

A new generation of oil-electric hybrid technology, energy saving and emission reduction, high efficiency and low heat, and greatly reduced working noise;

A new generation of oil-electric hybrid technology, energy saving and emission reduction, high efficiency and low heat, and greatly reduced working noise;

Silent when waiting for fast speed (about 25 dB), low noise when bending and returning (the pressure in the hydraulic system is controlled by the main servo motor closed loop);

Silent when waiting for fast speed (about 25 dB), low noise when bending and returning (the pressure in the hydraulic system is controlled by the main servo motor closed loop);

High-performance motor and oil pump, strong power;

High-performance motor and oil pump, strong power;

Ram idling, fast movement, pressure retention, and return noise are significantly reduced, more than 30% lower than other noise, while running more smoothly;

Ram idling, fast movement, pressure retention, and return noise are significantly reduced, more than 30% lower than other noise, while running more smoothly;

|

Machine design Finite element analysis of the whole machine: A professional actuary uses Ansys software to carry out finite element analysis of the strength and rigidity of the entire machine on the frame, slide, table, and vertical plate of each piece of equipment to ensure the machine's service life. |

|

|

Heat treatment The frame adopts an all-steel integral welding structure, eliminates the internal stress of the body and important welding parts through normalizing and high-frequency vibration, ensures the overall accuracy of the machine tool, has excellent stiffness, and has excellent anti-distortion and anti-tilt ability. Ensure the long-term stability of the machine |

|

|

Frame welding The weld has no welding defects such as edge bite, porosity, crack, etc. The outer surface of the welding is polished and smooth, and the overall plane of the equipment is smooth and bright without convex and concave. |

|

|

Frame welding The weld has no welding defects such as edge bite, porosity, crack, etc. The outer surface of the welding is polished and smooth, and the overall plane of the equipment is smooth and bright without convex and concave. |

|

|

Complete assembly Detailed operation instructions and experienced technical workers ensure that each link is accurately in place and divided according to functional areas for streamlined operations. |

|

|

Control system Provide different brands of systems according to customer requirements,such as Delem,Cybelec,Esa or Domestic brands. |

|

|

Optical Scales Equip with Italy GIVI.High precision of gratings whose linear thermal expansion is suitable for the application required. Measuring lengths up to 30 m, accuracy grade up to ± 1 µm and resolutions up to 0.01 µm. Certificate of metrological inspection supplied with each scale. |

|

|

The main servo motor adopts the first-line brand Huichuan ignorance servo motor ◆ 1. High precision: The electric control system of the Huichuan servo motor is equipped with an encoder, which can accurately obtain the position signal, and the control positioning error is small, thus ensuring high-precision motion control. ◆ 2. Fast response: The response speed of the Huichuan servo motor is very fast, and it can respond to the control signal in microseconds to achieve fast and accurate dynamic control. ◆ 3. Strong control performance: The controller of the Huichuan servo motor can control the speed, position, acceleration, and other parameters of the motor, and can monitor the changes of various parameters in real-time to adapt to different control needs. ◆ 4. Good stability: Huichuan servo motor has an automatic adjustment function, which can automatically identify load changes and make timely adjustments to ensure the stability of the movement. |

|

|

Crowning Our Electric compensation workbench adopts an inclined block combination structure. Different inclined block groups use different inclined surface configurations, and the matching accuracy can reach 0.02mm. The upper and lower inclined block groups move relative to each other in the length direction to generate compensation for the flexible deformation of the bending machine. At the same time, the left and right brackets can be opened with T-slots, and the cover plate can be opened with mold installation slots; the motor drive adopts a customized CNC integrated motor, which can be perfectly connected with the CNC system of the Press Brake. |

|

|

Hydraulic system ● The electro-hydraulic servo system is used to control the double cylinders synchronously in a closed loop, with high synchronous control accuracy, and the bending accuracy and repeated positioning accuracy also reach a high level. |

|

|

Backgauge The back gauge has fast speed and high positioning accuracy. |

|

|

Quick Clamp Equipped with manual quick clamp |

|

|

Electrical system The main components of the machine's electrical control system use the internationally famous brand Schneider/ Siemens, stable and durable. |

|

|

Moveable Front Support System Moveable front support, moving along the linear guide rail, can be parked atany position,with rotation and height adjustment functions to help you to bend. |

|

|

Laser protection (optional) Bending machines with DSP visible laser protection, compliant with EN12622. The beam protects the bender operator's fingers from the danger of squeezing between the punch and the die. |

|

|

High-quality mold The alliance mold (integral quenching), the use of 42crmo (42 chromium molybdenum) as a high-quality mold material, after perfect heat treatment process (integral quenching, laser quenching, nitriding treatment), to ensure the bearing capacity and service life of the mold. Adopt high-end precision machine tool processing to ensure high-precision mold. |

|

|

C-type throat compensation device The C-type throat compensation device is installed below the throat of the machine tool and connected to the detection device above. Slight deformation of the machine tool due to bending force will not affect the measurement accuracy of the system, ensuring the bending accuracy of plates of any thickness and any material. |

|

|

Precision fast clamping system One-click rapid clamping and releasing the uppertooling,fixtures can be realized at the bottom andlateral two-way upper tooling installation andreplacement,can effectively reduce changeover timeand improve production efficiency. |

|

|

Dual linear guide rail structure Novel and unigue double linear guide structureensures excellent positioning accuracy. |

|

|

Reinforcement beam Press Brake slider slider reinforces the crossbeam to effectively enhance the stability of the slider and ensure bending accuracy. |

|

-

Mar 26,2025 _ShuaibiaoIn the realm of industrial manufacturing, precision is paramount. A shearing machine, essential for cutting through various metals and materials, demands meticulous adjustment to ensure flawless opera...Read More

-

Mar 20,2025 _ShuaibiaoIn the realm of precision metal fabrication, the press brake machine stands as an indispensable tool, shaping metal sheets into intricate forms with remarkable accuracy. Among its many tooling options...Read More

-

Mar 14,2025 _ShuaibiaoThe hydraulic swing beam shearing machine is a pivotal tool in the metalworking industry, renowned for its precision and efficiency. However, achieving optimal performance depends significantly on con...Read More

What measures has Ordinary CNC electric hydraulic servo press brake machine taken to prevent wear and tear on key components of the machine?

The Ordinary CNC electric hydraulic servo press brake machine employs several key measures to minimize wear and tear on its critical components. These preventative measures help extend the machine’s service life, reduce maintenance costs, and ensure reliable performance. Here are some of the steps taken to prevent wear and tear:

Advanced Oil-Electric Hybrid System:

The integration of an oil-electric hybrid system helps optimize energy usage, reducing strain on the machine’s hydraulic system and servo motor. By efficiently managing power, the system minimizes excessive wear on key components, particularly those subject to high loads and stresses.

This system also reduces heat generation, a primary cause of wear in hydraulic systems. Lower operating temperatures mean less thermal stress on parts, including seals, bearings, and hydraulic fluid.

Precision Servo Motor Control:

The machine uses servo motors for precise control over movement, ensuring smoother operations. The servo motor’s closed-loop system adjusts the hydraulic pressure to optimal levels, preventing unnecessary stress on the hydraulic components. This precise control leads to reduced mechanical wear, especially during repeated bending cycles.

Lower stress on moving parts during operations such as bending, returning, and pressure retention translates to less friction and wear on mechanical joints, actuators, and guide rails.

Hydraulic System with Pressure Control:

The closed-loop hydraulic system continuously monitors and adjusts the pressure to prevent over-pressurization, which can cause damage to hydraulic components. This ensures that the cylinders, pumps, and valves are subjected to minimal wear, prolonging their lifespan.

The hydraulic oil used in the system is carefully regulated for temperature and cleanliness. Ensuring optimal oil quality prevents contaminants from damaging components like pumps and valves, while maintaining proper viscosity prevents overloading and internal wear.

Heat Treatment of Frame and Components:

The frame and other key parts of the machine undergo heat treatment processes, such as normalizing and high-frequency vibration stress relief. These treatments enhance the rigidity and durability of the structure, preventing warping or distortion under stress and reducing the likelihood of mechanical fatigue over time.

Wear-Resistant Materials:

Key components, such as tooling surfaces, guide rails, and sliders, are often made from wear-resistant materials or coated with surface hardening treatments. These materials are designed to withstand repetitive stress, reducing wear and extending the operational life of parts that come into direct contact with the workpiece or undergo constant movement.

Smooth, Polished Welding:

The frame's polished and smooth welds prevent stress concentrations that could lead to cracks or early failure. This approach helps in maintaining the structural integrity of the frame, especially in areas subject to constant stress, reducing the risk of wear on the overall machine structure.

Reduced Noise and Vibration:

The machine is designed to operate with low noise and vibration, particularly in key movements such as ram idling and returning. Reducing vibrations helps protect components from long-term fatigue, especially bearings, motors, and hydraulic pumps, which are highly susceptible to vibration-related wear.

Efficient Lubrication Systems:

Automated lubrication systems ensure that moving parts are continuously supplied with the correct amount of lubrication, reducing friction and wear. Regular lubrication minimizes wear on sliding surfaces like guide rails and bearings, and extends their operational life.

Preventive Maintenance Alerts:

Many CNC press brake machines come equipped with monitoring systems that alert operators when maintenance is required, based on operating hours or stress levels. These systems can prevent components from being worn down excessively before repairs or replacements are made.

The Ordinary CNC electric hydraulic servo press brake machine uses a combination of advanced hybrid systems, servo motor control, pressure management, wear-resistant materials, heat-treated components, and optimized lubrication to minimize wear and tear on its key components. These measures help ensure long-term durability, reduce operational downtime, and maintain the machine’s precision and efficiency over time.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى