NC Press Brake

STANDARD FEATURES

E21S system

E21S system

Standard mould

Standard mould

Fast clamp

Fast clamp

Standard backgauge Y1, Y2, X

Standard backgauge Y1, Y2, X

OPTIONAL FEATURES

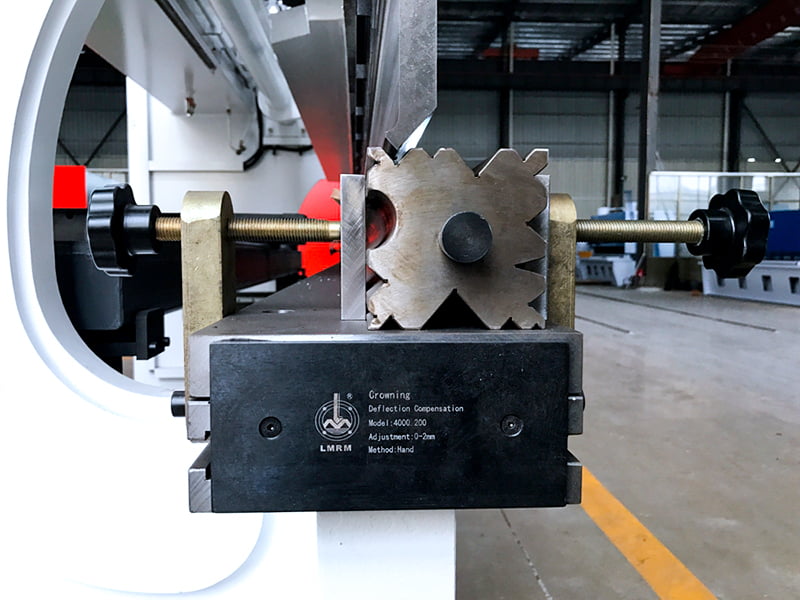

Manual crowning

Manual crowning

Servo motor

Servo motor

DF41 system

DF41 system

|

CNC 1. High-definition LCD display, with Chinese and English languages available, one page displays programming parameters, which makes programming faster and more convenient. 2. X and Y axes can only be positioned, and can also be manually adjusted as needed, removing the mechanical hand-cranked positioning device. 3. Built-in pressure holding time and unloading delay setting functions, which are easier to operate, do not require time relays, and reduce costs. 4. It has a one-key backup and restore function for parameters, which can restore parameters at any time as needed to reduce maintenance costs. 5. Supports multi-step programming, complex workpieces can be processed in one go, improving production efficiency and processing accuracy. 6. All buttons on the panel are micro switches, which have been strictly tested for EMC, high and low temperature, vibration, etc. to ensure the stability and service life of the product. 7. Passed CE certification to meet overseas market needs. |

|

|

Electrical box The electrical parts of our machines are made of Schneider parts, which are stable and durable, ensuring a long service life and stable electrical operation. |

|

|

Gear pump Our machines use American Sunny brand gear pumps, which have low operating noise and are made of high-strength cast iron. They have a unique internal noise reduction design and are able to withstand high pressures. |

|

|

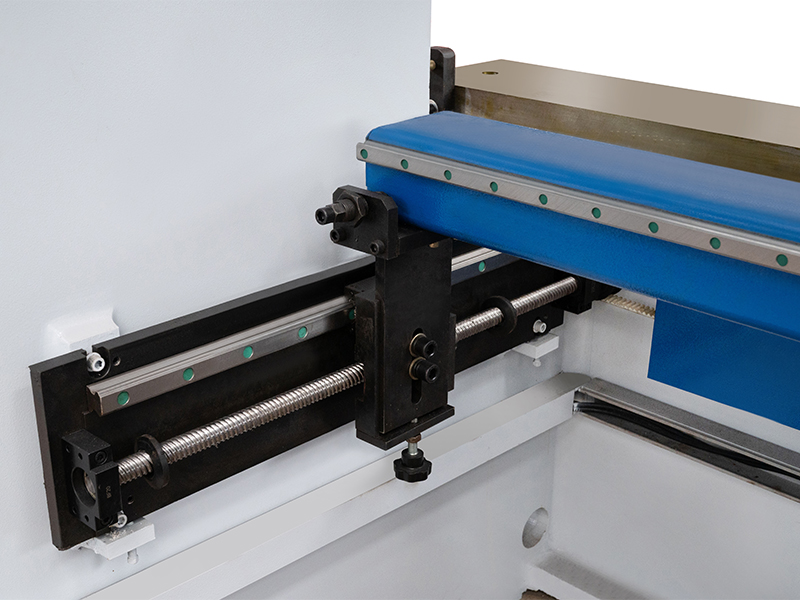

Back gauge The machine adopts a self-designed high-precision back gauge assembly, equipped with a high-precision ball screw, adjustable back gauge finger, and manual lifting function. |

|

|

Mould We can provide the right tooling options based on your specific bending requirements. Our dies are built to last. |

|

|

Front support Moving along the linear guide rail, it can be docked at any position to assist the bending work and make the work efficient. Fixed type is standard for individual models. |

|

|

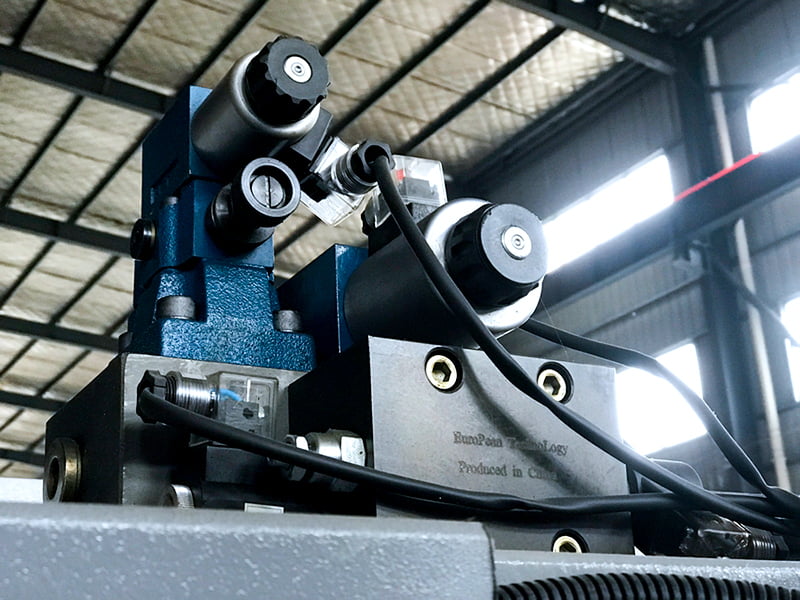

Hydraulic system High-quality hydraulic valves are used, especially the Rexroth brand. These valves can withstand high pressure, are durable, and almost do not need maintenance. |

|

|

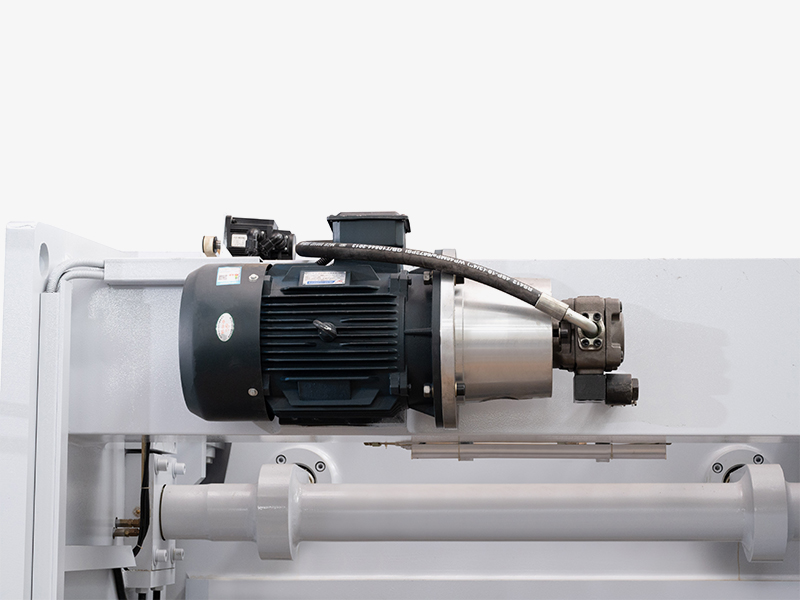

Main motor It adopts well-known brand domestic motors, which have the characteristics of high efficiency and energy saving, large starting torque, excellent performance, low noise, low vibration and high reliability. |

|

|

Torsion-sync structure The torsion synchronization principle controls the movement of the bending machine slide. |

|

|

Manual compensation workbench |

|

-

Feb 05,2026 _ShuaibiaoA shearing machine is a mechanical cutting device that uses two sharp blades moving past each other to cut sheet metal, plates, and other materials in a straight line. Unlike sawing or drilling, shea...Read More

-

Jan 30,2026 _ShuaibiaoUnderstanding What a Plate Rolling Machine Does A plate rolling machine, also known as a metal plate rolling machine or plate bending machine, is used to shape flat metal sheets into cylindrical, coni...Read More

-

Jan 23,2026 _ShuaibiaoIntroduction to V-Grooving Machines V-grooving machine is specialized cutting tools designed to create precise V-shaped grooves on various sheet materials. They are widely used in industries such as w...Read More

How does the ordinary torsion axis synchronous press brake machine accurately maintain the angular consistency of the entire length of the workpiece during the bending process?

The ordinary torsion axis synchronous press brake machine maintains angular consistency across the entire length of the workpiece through its torsion shaft synchronization mechanism. Here’s a breakdown of how this system works to achieve consistent bending angles:

Torsion Shaft Synchronization Mechanism

The torsion shaft is a rigid mechanical link that connects both ends of the press brake machine, synchronizing the movement of the upper beam (ram) during the bending process.

This shaft acts like a rotational spring, ensuring that when one side of the machine moves, the other side moves precisely in sync. This linkage prevents any side-to-side tilt or misalignment, which is crucial for maintaining uniform pressure along the entire length of the workpiece.

Distribution of Force

The torsion shaft evenly distributes the force exerted by the ram across both sides of the machine. This uniform force application means that the bending angle remains consistent from one end of the sheet to the other.

As the upper die presses down on the sheet, the shaft counteracts any potential discrepancies caused by the mechanical tolerances, ensuring that the bending pressure is the same on both sides.

Mechanism Design and Rigidity

The rigid design of the torsion axis prevents any deflection or twisting during the bending operation, which is a common issue with non-synchronized machines. This rigidity is crucial to maintaining the angular precision of the bend.

Any slight movement or flex in one side of the machine is immediately compensated by the torsion shaft, which maintains the parallelism of the upper and lower dies throughout the bending process.

Mechanical Balancing System

The torsion axis synchronous press brake machines often have a mechanical balancing system to correct any small imbalances that could lead to variations in angle. This system ensures that even if there are minor differences in the material properties or thickness along the length of the sheet, the angular consistency is not compromised.

The balancing mechanism works together with the torsion shaft to ensure that the upper beam descends uniformly, maintaining the desired bending angle along the full length of the workpiece.

Manual Adjustments and Calibration

These machines usually allow for manual adjustments to fine-tune the bending parameters. Operators can make slight modifications to the position of the dies or the pressure settings to account for variations in the material or machine wear over time.

Regular calibration of the machine and the torsion shaft is also a standard practice to ensure that the system maintains its precision capabilities over extended periods of operation.

Consistent Tooling and Die Alignment

Proper alignment of the upper and lower dies is crucial for maintaining angular consistency. The design of the ordinary torsion axis synchronous press brake machine ensures that the dies are perfectly aligned, reducing the chance of angular variation.

Using high-quality, consistent tooling that fits precisely with the die setup also contributes to uniform bending angles throughout the entire workpiece.

Key Advantage: Simplicity and Reliability

One of the key benefits of using a torsion axis synchronous system is its mechanical simplicity. Unlike complex CNC or hydraulic systems that rely on sensors and automated controls, the torsion shaft provides a reliable and straightforward solution for maintaining consistent bending angles, making it easy to operate and maintain.

Limitations:

Despite its advantages, this system has its limitations when compared to CNC-controlled machines. It is less capable of handling highly complex bends or compensating for variances in material properties in real-time.

The manual adjustments and dependence on mechanical linkages mean that while it is effective for simpler tasks, achieving ultra-high precision might be challenging without operator intervention.

The ordinary torsion axis synchronous press brake machine uses the torsion shaft to synchronize the movement of both ends of the ram, ensuring even force distribution and mechanical stability. This results in consistent angular bending across the entire length of the workpiece, making it suitable for straightforward bending operations where precise synchronization is required.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى