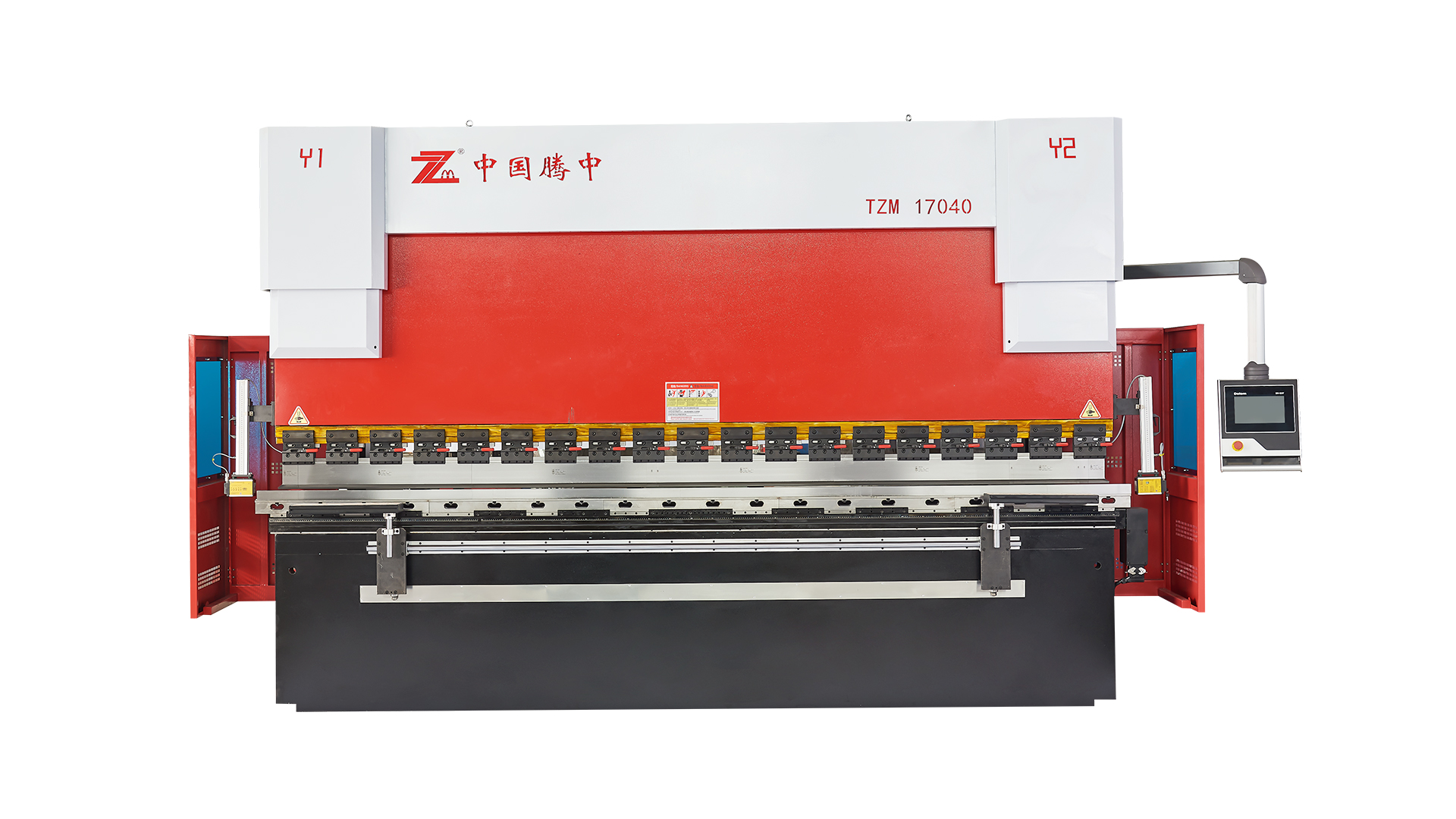

Does the CNC electro hydraulic servo press brake machine have features to reduce setup time, such as automatic tool clamping or a quick-change system?

Many CNC electro-hydraulic servo press brake machine come equipped with features specifically designed to reduce setup time, which can significantly enhance overall productivity. Here are a few key features that can help minimize setup times:

Automatic Tool Clamping

Automatic tool clamping systems are often integrated into modern CNC press brakes, allowing for faster and more efficient tool changes. This feature automates the process of clamping and unclamping bending tools, eliminating the need for manual tightening.

These systems ensure that tools are clamped with consistent pressure and alignment, improving accuracy and reducing the time operators spend on adjustments.

Quick-Change Tooling System

A quick-change system allows for rapid changes between different tooling setups. These systems can include features like interchangeable punch and die holders, which enable operators to switch tools without the need for additional adjustments.

This is especially useful when transitioning between different bending tasks, making it easier to switch from one job to another with minimal downtime.

Automatic Backgauge Adjustment

Automatic backgauge systems adjust the position of the backgauge fingers to accommodate different bending lengths and angles quickly. This feature allows the press brake to adjust itself to various job requirements without requiring manual input, which saves time during setup.

The backgauge can be programmed directly through the CNC interface, ensuring that each setup is accurate and consistent.

Offline Programming and CAD/CAM Integration

Many CNC press brakes support offline programming through CAD/CAM software. This means that the bending programs can be prepared before the actual job setup, minimizing the time required on the shop floor.

Designs can be uploaded directly to the CNC system, allowing the operator to start the job immediately without needing to manually input each step.

Laser or Optical Alignment Systems

Some models include laser or optical alignment systems that help align tools and materials quickly, further reducing setup time. This ensures that the positioning of materials is precise, allowing for faster start times and reduced trial-and-error adjustments.

Automatic Crowning System

An automatic crowning system adjusts the table's curvature to ensure consistent bending results across different materials and thicknesses. This eliminates the need for manual shimming or adjustments, saving time during initial setup for each bending operation.

These features combined make CNC electro-hydraulic servo press brake machine highly efficient, especially in environments where frequent tooling changes are required. By minimizing setup times, these systems not only improve productivity but also help reduce the skill level required for operators, making it easier to maintain a smooth workflow.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى