What makes the CNC 4 roller plate rolling machine a game changer in metal forming?

2024-12-06

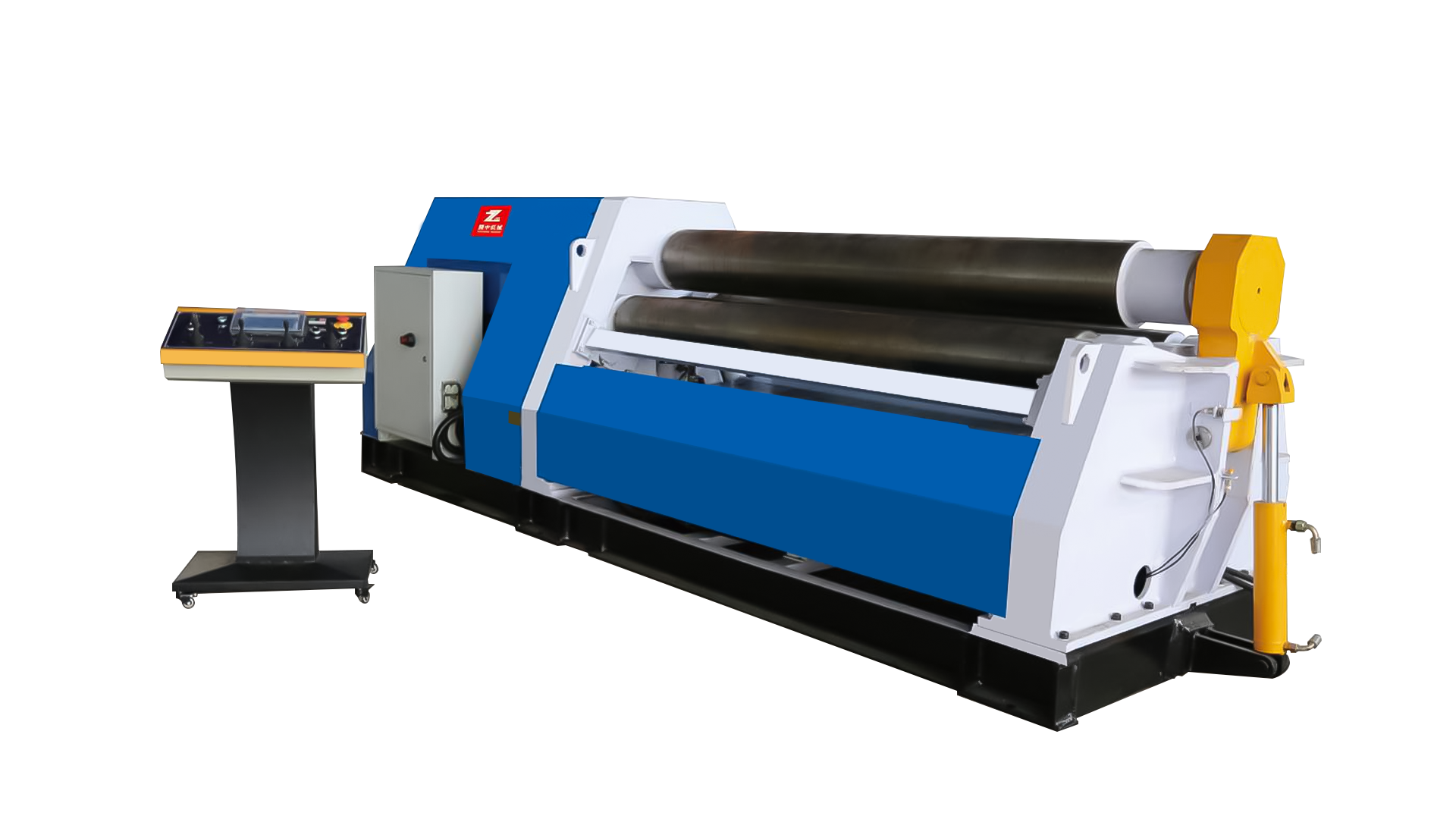

In the world of precision metalworking, the CNC 4 roller plate rolling machine stands as a cornerstone of advanced manufacturing. Combining cutting-edge technology with robust engineering, this machine offers unparalleled efficiency, accuracy, and flexibility in bending sheet metal and plates to specific forms.

Precision at Its Core

The hallmark of the CNC 4 roller plate rolling machine is its ability to deliver precise results with exceptional repeatability. Unlike traditional rolling machines, which rely on manual adjustments and less sophisticated control systems, the CNC version uses a computer numerical control (CNC) system to automate and fine-tune the entire process. This automation not only reduces human error but also optimizes the rolling process, ensuring that each part is consistent and within the desired specifications. The digital interface allows operators to input exact parameters, which the system then follows with meticulous accuracy.

Superior Control and Flexibility

With four rollers, this machine offers superior control compared to the conventional three-roller models. The top roller serves as the primary working roller, while the two bottom rollers help guide the metal sheet, ensuring an even and controlled bend. The fourth roller, strategically placed, provides additional support to the sheet, helping eliminate material deformation. This configuration allows for a wider range of bending radii, accommodating both thick and thin materials, making it suitable for various industries, from aerospace to construction.

Unmatched Efficiency

The CNC 4 roller plate rolling machine is designed for optimal performance with reduced setup times. Its advanced control system minimizes manual intervention, accelerating production cycles and reducing downtime. This machine excels in producing high volumes of parts with exacting tolerances. In industries where time is of the essence, this efficiency translates into significant cost savings and faster turnaround times, making it an invaluable asset in any fabrication shop.

Robust Build, Reliable Performance

Built to endure the demands of heavy-duty operations, the CNC 4 roller plate rolling machine is constructed from high-quality materials, ensuring its longevity and resistance to wear. Its rigid structure prevents flexing and ensures that the machine maintains accuracy under pressure, even with high-strength metals. The ability to handle a wide array of materials—steel, aluminum, and even more complex alloys—further underscores its versatility and robustness in the face of diverse manufacturing needs.

Enhanced Safety and Ease of Use

Safety is a critical consideration in any industrial operation. The CNC 4 roller plate rolling machine is equipped with advanced safety features, such as automatic overload protection and an intuitive control interface. The user-friendly touchscreen provides real-time diagnostics, monitoring machine performance and minimizing the risk of operator error. In addition, the machine’s design prioritizes ease of maintenance, reducing the time and effort required to keep it in peak operating condition.

For any business looking to maximize production capabilities, increase precision, and streamline operations, the CNC 4 roller plate rolling machine is an indispensable tool. Its combination of advanced technology, flexibility, and durability makes it the ideal solution for industries requiring consistent, high-quality metal forming. Whether you are producing large batches of custom parts or tackling complex projects, this machine ensures that your production runs smoothly, efficiently, and with remarkable accuracy.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى