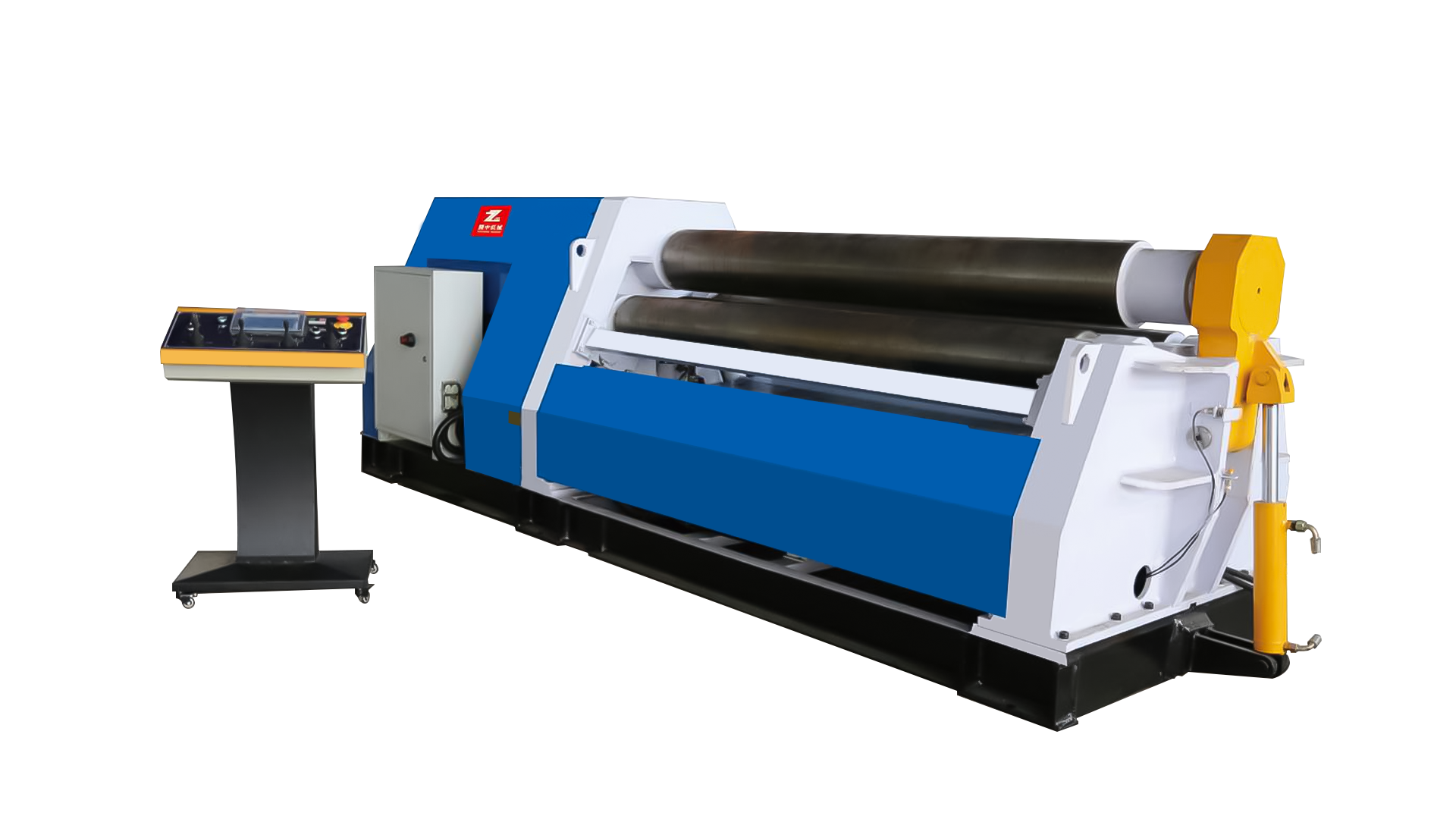

CNC electric servo four-roller plate rolling machine

A new generation of oil-electric hybrid technology, energy saving and emission reduction, high efficiency and low heat, and greatly reduced working noise;

A new generation of oil-electric hybrid technology, energy saving and emission reduction, high efficiency and low heat, and greatly reduced working noise;

Silent when waiting for fast speed (about 25 dB), low noise when bending and returning (the pressure in the hydraulic system is controlled by the main servo motor closed loop);

Silent when waiting for fast speed (about 25 dB), low noise when bending and returning (the pressure in the hydraulic system is controlled by the main servo motor closed loop);

High-performance motor and oil pump, strong power;

High-performance motor and oil pump, strong power;

Ram idling, fast movement, pressure retention, and return noise are significantly reduced, more than 30% lower than other noise, while running more smoothly;

Ram idling, fast movement, pressure retention, and return noise are significantly reduced, more than 30% lower than other noise, while running more smoothly;

|

Plate feed The side roll of the plate is automatically aligned immediately, and the principle of action is similar to that of the hydraulic ruler. The schematic diagram of the structure is as follows: |

|

|

Solid fuselage construction The accuracy of the rolling machine depends on the robustness of the frame and chassis. |

|

|

Engineering and production advantages The mechanical and hydraulic systems on the W12 machines are designed by experienced engineers. These engineers utilize parametric 3D engineering techniques and the implementation of static and institutional analysis to design machines. |

|

|

Roll and crown The most important component of the plate rolling machine is the roll itself. Most machines on the market have smaller diameters, and weaker rolls that deform and form flat points at the edge of the plate during pre-bending. |

|

|

Optional dynamic roll crown In some cases, the range of plate thickness may be very wide. In this case, it is necessary to use a dynamic roll crown system to eliminate the crown problem. The system is only used to support rolls of thin plates, while when bending thick plates, the hydraulic crown cylinder applies a negative crown to the rolls from the bottom to eliminate deflection that can occur during pre-bending. This system helps to obtain a smoother pre-bent edge. |

|

|

Coning device With excellent construction, a large body, and the ability to Angle the bottom and side rollers, you can easily bend wide-angle and small-diameter conical parts. |

|

|

Electrical system The driving method is to directly drive the worm gear of the ball screw lifter through a servo motor, and the worm gear drives the nut of the ball screw. The rotation of the nut causes the ball screw to rise and fall, and the ball screw is connected to the side roller seat, so that the side roller moves up and down, and the lower roller also moves in the same way. This method differs from other factories that use servo motors to drive hydraulic pumps, and then control the oil cylinder through proportional valves. The stroke of the oil cylinder is then fed back to the PLC through a displacement sensor. In terms of control, our company's method has a more direct control accuracy, and there is no accumulated error, which is a prerequisite for ensuring high-precision rolling. |

|

|

Ideal for clamping In the W12 series of roll bending machines, plate clamping is achieved by moving the strong torsion bar of the lower roll. The torsion bar is driven by 2 hydraulic cylinders to ensure optimal parallel clamping of the sheet. |

|

|

Optional side and top support systems Optional hydraulic side or top supports help prevent cylinder deformation when bending in large shapes. The side supports have hydraulic double cylinders and are made of heavy steel structure.

|

|

|

PLC control system (Standard) PLC electronic balance system ensures synchronous operation of lower and side rollers W12 series machines. The process is provided by a PLC and touch operation panel, which controls 6 axes. In addition, the ability to program up to 5 previously experienced bend value setpoints enables ease of use and time savings. Synchronous digital control of the left and right side rollers and the lower rollers must be in the operating state of the console. Down run control. The number of moves for each action is displayed on the touchscreen interface for easy and intuitive operation. Due to the work of the left and right side rollers and the lower rollers, the work of the tipping frame adopts hydraulic power. Start the oil pump motor before moving. |

|

-

Dec 20,2024 _ShuaibiaoIn the world of sheet metal fabrication, the selection of cutting equipment plays a critical role in determining the precision, efficiency, and overall quality of the finished product. Among the many ...Read More

-

Dec 13,2024 _ShuaibiaoIn the world of precision sheet metal fabrication, the back gauge mechanism plays a pivotal role in ensuring accuracy and efficiency during the shearing process. A back gauge, integral to the operatio...Read More

-

Dec 06,2024 _ShuaibiaoIn the world of precision metalworking, the CNC 4 roller plate rolling machine stands as a cornerstone of advanced manufacturing. Combining cutting-edge technology with robust engineering, this machin...Read More

How energy efficient is a CNC electric servo four-roller plate rolling machine compared to a full hydraulic system?

A CNC electric servo four-roller plate rolling machine is generally more energy efficient than a fully hydraulic system due to the following key factors:

Precision Control

Servo motor-driven systems provide highly precise control of torque and movement. Unlike traditional hydraulic systems that often run continuously, the servo system only uses energy when active, significantly reducing idle power consumption.

Hydraulic systems usually operate at a constant speed and pressure, even when full power isn't required, leading to wasted energy. In contrast, a servo motor can adjust speed and power output dynamically, consuming energy only as needed for specific operations.

Reduced Heat Generation

Servo systems generate less heat because they don’t rely on constantly pressurized hydraulic fluid. Less heat means less energy is spent on cooling and maintaining system efficiency. Additionally, lower heat generation translates to improved component longevity and reduced wear and tear.

Hydraulic systems, on the other hand, generate significant heat due to fluid compression and friction, requiring additional energy for cooling systems.

Energy Recovery Capabilities

Electric servo motors often have energy recovery systems, especially during deceleration or braking phases. This means energy that would otherwise be wasted is recaptured and reused, contributing to overall efficiency.

In hydraulic systems, energy recovery is much less common, as hydraulic fluids do not easily allow for such recapturing of energy.

Quieter and More Efficient Standby Mode

When the machine is idle, servo-driven systems can enter low-power modes or shut off entirely, consuming minimal energy. These systems are extremely quiet, contributing to both energy savings and a more pleasant working environment.

Hydraulic systems tend to maintain constant pressure even when idle, which requires continuous power to maintain that state, leading to higher energy consumption during downtime.

Long-Term Energy Savings

Over time, the servo system provides cumulative energy savings, especially for operations that require frequent start-stop motions, variable speeds, or high-precision work. The system adjusts power requirements dynamically, preventing unnecessary energy use.

Hydraulic machines, while often simpler and more robust in some heavy-duty applications, do not offer the same fine-tuned energy management, leading to higher operational costs over extended periods.

CNC electric servo four-roller plate rolling machine can be 20-50% more energy efficient compared to a full hydraulic system, depending on the application and operational conditions. This difference is primarily due to the servo system's ability to dynamically adjust power, reduce idle energy consumption, lower heat generation, and recover energy.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى