What are the primary types of press brake machines, and how do they differ in terms of functionality and application?

2024-09-02

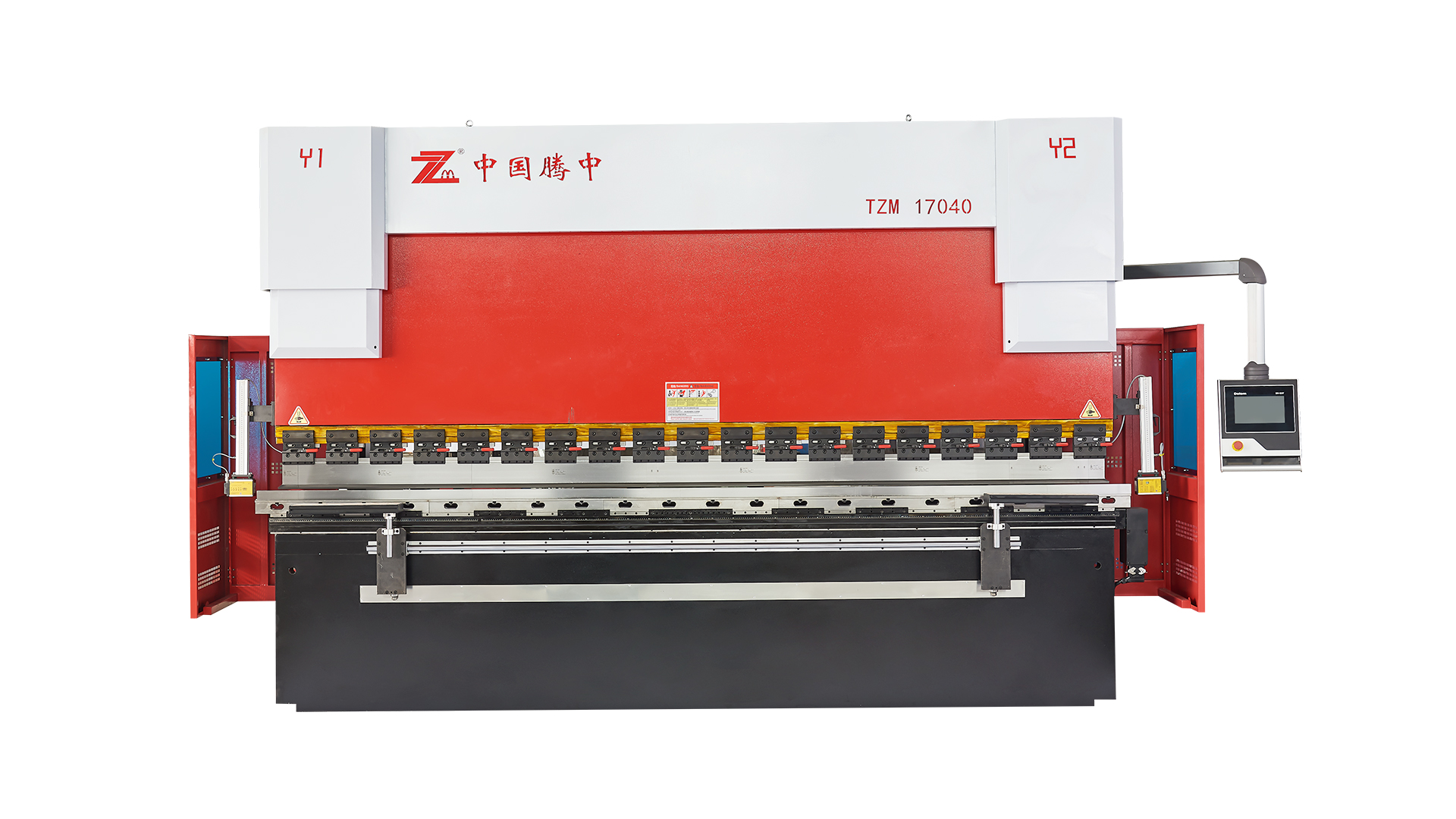

Press brake machine is the unsung heroes of the metal fabrication industry, bending and shaping metal sheets into precise forms. Whether you’re a seasoned fabricator or a curious beginner, understanding the different types of press brakes can help you make informed decisions for your projects.

Mechanical Press Brakes: The Workhorses of the Industry

Mechanical press brakes are the classic machines that have been around for decades. They operate using a toggle mechanism that converts rotational motion into linear motion, allowing for quick and repetitive bending.

Functionality:

These machines are known for their speed and efficiency. They can deliver a high tonnage force, making them ideal for bending thick materials. However, they may not offer the same level of precision or control as other types.

Applications:

Mechanical press brakes are often used in high-volume production settings where speed is crucial. Industries like automotive and appliance manufacturing frequently rely on them for tasks such as producing brackets, frames, and other structural components.

Hydraulic Press Brakes: The Precision Masters

Hydraulic press brakes utilize hydraulic cylinders to generate bending force, providing greater control over the bending process. This type of press brake is suitable for a wide range of materials and thicknesses.

Functionality:

One of the standout features of hydraulic press brakes is their ability to maintain consistent pressure throughout the bending process. They can easily handle complex bends and are equipped with CNC (Computer Numerical Control) systems for enhanced precision.

Applications:

These machines are favored in industries requiring intricate designs, such as aerospace and architectural fabrication. Hydraulic press brakes are often used for tasks like custom metalwork, where accuracy is paramount.

Electric Press Brakes: The Eco-Friendly Innovators

Electric press brakes represent the latest evolution in bending technology. They use electric motors to drive the bending process, resulting in lower energy consumption and reduced carbon footprints.

Functionality:

With advanced control systems, electric press brakes offer exceptional precision and repeatability. They can also operate at a lower noise level compared to their mechanical and hydraulic counterparts, making them more pleasant to work around.

Applications:

These machines are ideal for industries looking to minimize their environmental impact while maintaining high-quality output. Electric press brakes are increasingly popular in sectors such as renewable energy and electronics manufacturing, where precision and sustainability go hand in hand.

When it comes to choosing the right press brake machine, understanding the different types available is crucial. Mechanical press brakes excel in high-speed, high-volume production; hydraulic press brakes offer unmatched precision for intricate designs; and electric press brakes are paving the way for eco-friendly manufacturing practices. Each type brings its own set of advantages tailored to specific applications. By selecting the appropriate press brake for your needs, you can enhance efficiency, accuracy, and sustainability in your metal fabrication processes. So, whether you’re bending metal for a new project or just exploring your options, now you’ve got the knowledge to make an informed choice!

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى