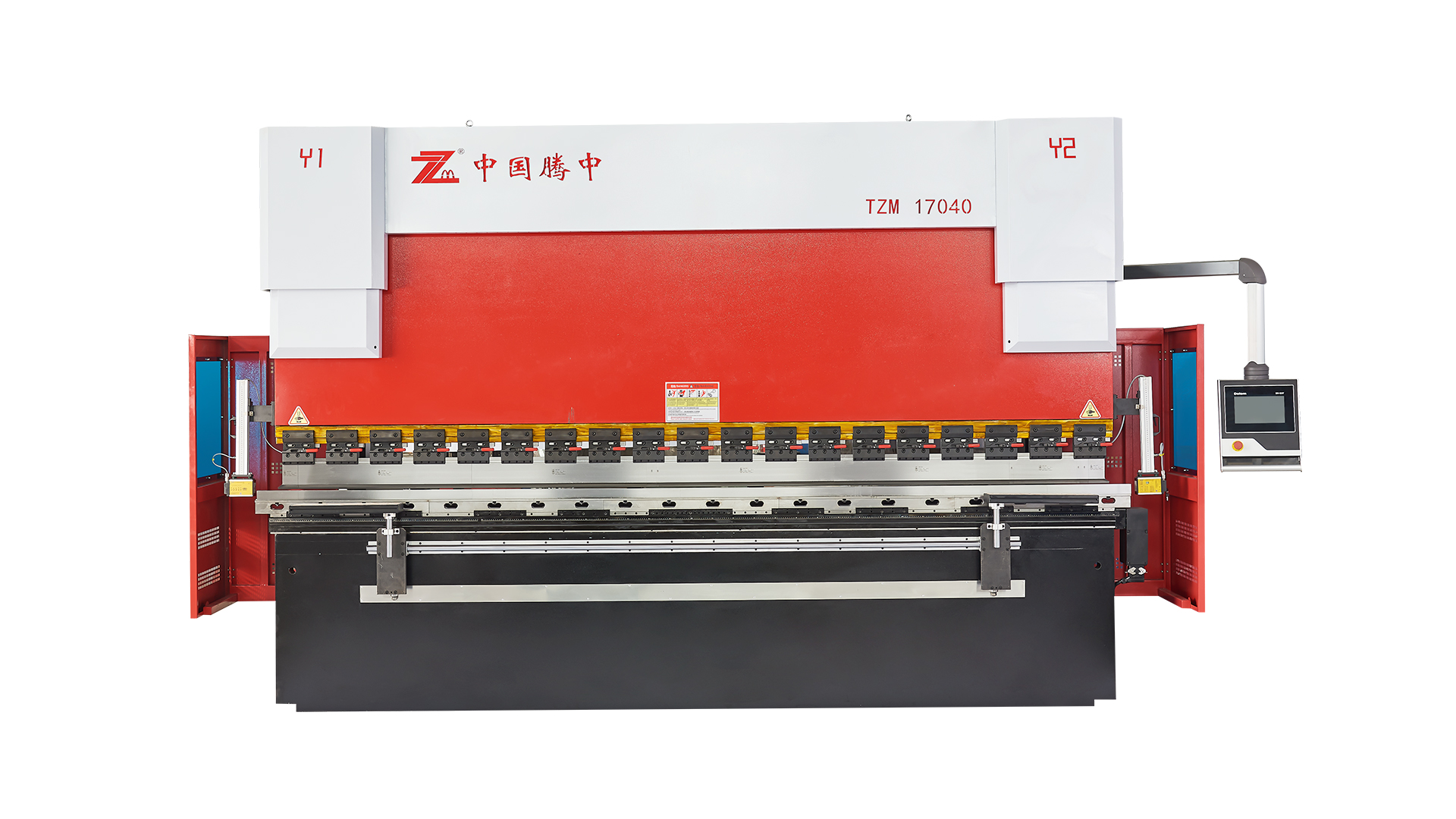

CNC hydraulic guilotine Shearing Machine

A CNC hydraulic guillotine Shearing Machine is an advanced metal sheet cutting equipment using a CNC system to control the cutting process, can precisely control the cutting length and cutting Angle, and improve the processing accuracy and production efficiency. Using the brake structure, including the upper and lower tools, the up and down movement of the upper tool is controlled by the numerical control system to realize the cutting of the metal sheet. The CNC system can monitor and adjust the cutting parameters in real-time, ensure the high precision and consistency of the cutting products, and meet various processing requirements.

|

Europe's newest technology |

|

|

Standard Estun E21 system |

|

|

Vertical adjustment device and front stop position device |

|

|

Simple and effective adjustment device through |

|

|

High-precision back gauge |

|

|

Automatic back gauge swing-up device |

|

|

Lighting alignment device |

|

|

Good quality blades |

|

|

Working table steel ball transfer structure |

|

|

New and practical protected device |

|

|

Delem DAC360 system(optional) |

|

|

Pneumatic sheet support device(suitable for CNC hydraulic guillotine shears)(optional) |

|

|

Moveable front support arm (can be optional brush plate) |

|

|

Angle positioning device(optional) |

|

|

CNC front feeding device (optional) |

|

-

Mar 26,2025 _ShuaibiaoIn the realm of industrial manufacturing, precision is paramount. A shearing machine, essential for cutting through various metals and materials, demands meticulous adjustment to ensure flawless opera...Read More

-

Mar 20,2025 _ShuaibiaoIn the realm of precision metal fabrication, the press brake machine stands as an indispensable tool, shaping metal sheets into intricate forms with remarkable accuracy. Among its many tooling options...Read More

-

Mar 14,2025 _ShuaibiaoThe hydraulic swing beam shearing machine is a pivotal tool in the metalworking industry, renowned for its precision and efficiency. However, achieving optimal performance depends significantly on con...Read More

What are the safety features commonly found in CNC hydraulic guilotine shearing machine?

CNC hydraulic guillotine shearing machine is equipped with several safety features to protect both the operator and the machine. Here are some of the commonly found safety features:

Protective Fencing and Light Curtains

Protective fencing: Surrounds the machine to prevent unauthorized access to the cutting area during operation.

Light curtains: Infrared beams that act as a virtual barrier. If an object or person interrupts these beams, the machine stops immediately to prevent accidents.

Emergency Stop Buttons

Strategically placed around the machine, these emergency stop buttons allow the operator or other personnel to halt the machine instantly in case of any malfunction or hazardous situation.

Two-Handed Control System

Many CNC hydraulic guillotine shearing machines require two-handed operation to initiate the cutting process. This ensures that the operator's hands are safely away from the cutting area, reducing the risk of injury.

Safety Guards or Shields

Mechanical guards are placed near the cutting area to prevent direct contact with the blades during operation. These shields can be transparent to allow visibility but still offer protection.

Hydraulic Overload Protection

The machine is often equipped with hydraulic overload protection, which ensures that if the machine experiences excessive pressure or load during cutting, it shuts down or reduces pressure to avoid damage and injury.

Foot Pedal with Safety Feature

The foot pedal, used to control the cutting operation, often comes with a safety interlock that prevents the machine from operating if the pedal is pressed unintentionally.

Blade Gap Adjustment Sensors

Sensors that monitor the blade gap and ensure it is correctly set for the material being cut, reducing the chances of blade jamming or damage to the material and machine.

Anti-Backflow Safety Valve

This valve ensures that hydraulic pressure doesn’t build up unexpectedly, which could otherwise cause uncontrolled movements of the cutting blade.

Automatic Machine Locking System

When the machine is not in use or during maintenance, an automatic locking system may engage to prevent accidental starting of the machine.

Audible and Visual Alarms

Alarms alert operators to any malfunction or unsafe condition before, during, or after operation. This helps to reduce accidents by providing immediate feedback about any issues.

These safety features are crucial in CNC hydraulic guillotine shearing machine to ensure a secure working environment, prevent accidents, and enhance operational efficiency.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى