CNC Hydraulic Swing Beam Shearing Machine

CNC hydraulic swing beam shearing machine is an advanced metal sheet cutting equipment that uses a numerical control system to control the cutting process, can precisely control the cutting length and cutting angle, and improves processing accuracy and production efficiency. The up-and-down motion and swing of the upper knife are controlled by the hydraulic system to realize the shear processing of the metal sheet. The CNC system can monitor and adjust the cutting parameters in real time, ensure the high precision and consistency of the cutting products, and meet various processing requirements. With automated processing procedures and models, automated production can be achieved, production efficiency can be improved, and labor costs can be reduced. Suitable for steel structure, shipbuilding, automobile manufacturing, metallurgy, and other industries, is a common metal sheet processing equipment.

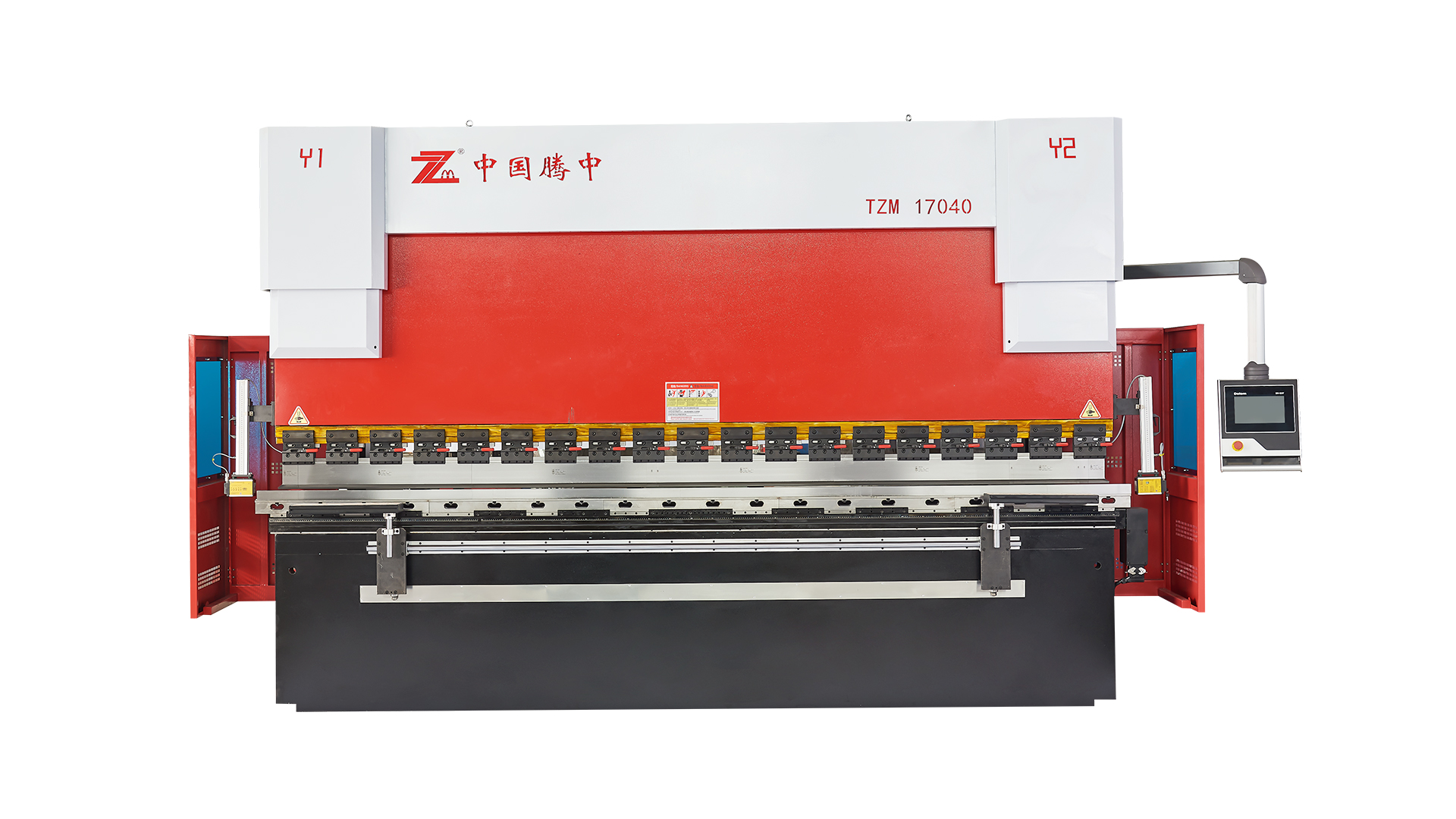

Simple European-style appearance, comfortable ergonomic design, practical and efficient reliability, high performance-price ratio, and low failure rate CNC hydraulic swing beam shearing machine.

|

Stroke Adjust Device of Backguage |

|

|

Manual Blade Gap Adjustment |

|

|

Cutting Sleeve and Joint |

|

|

Front Table |

|

|

Controller |

|

|

Main Motor |

|

|

Hydraulic System |

|

|

Electric Cabinet |

|

|

Hold Downs |

|

|

High Quality Blade |

|

-

Mar 26,2025 _ShuaibiaoIn the realm of industrial manufacturing, precision is paramount. A shearing machine, essential for cutting through various metals and materials, demands meticulous adjustment to ensure flawless opera...Read More

-

Mar 20,2025 _ShuaibiaoIn the realm of precision metal fabrication, the press brake machine stands as an indispensable tool, shaping metal sheets into intricate forms with remarkable accuracy. Among its many tooling options...Read More

-

Mar 14,2025 _ShuaibiaoThe hydraulic swing beam shearing machine is a pivotal tool in the metalworking industry, renowned for its precision and efficiency. However, achieving optimal performance depends significantly on con...Read More

How does automation in the CNC hydraulic swing beam shearing machine contribute to reducing labor costs and improving production efficiency?

Automation in CNC hydraulic swing beam shearing machine plays a significant role in reducing labor costs and improving production efficiency. Here's how:

Minimizes Manual Intervention

Automated cutting processes reduce the need for constant manual operation. Once the parameters are set in the CNC system, the machine can handle repetitive tasks with precision. This means fewer operators are required, resulting in lower labor costs and reduced human error.

Increases Production Speed

Automation allows for faster processing cycles as the machine can execute cutting operations continuously without pauses for manual adjustments. This leads to higher production throughput, enabling businesses to handle larger volumes of work in less time.

Real-Time Adjustments

The CNC system can monitor and adjust cutting parameters in real-time, adapting to material variations or changes in design requirements. This capability enhances accuracy and consistency without manual reconfiguration, speeding up the production process and reducing downtime.

Optimizes Material Usage

Automated systems in CNC machines optimize the layout of cuts to reduce material wastage. By calculating the most efficient cutting paths, the CNC system maximizes the usage of each metal sheet, minimizing scrap and lowering material costs.

Reduces Setup Time

Traditional manual machines often require significant time to set up for each job, especially when switching between different cuts or materials. With automated programming, setup time is dramatically reduced, and job changes can be handled swiftly by loading pre-programmed settings.

Improves Precision and Consistency

Automation ensures consistent quality in each cut, regardless of the operator’s skill level. The CNC system can precisely control the cutting angle, length, and speed, resulting in uniform output and reducing the need for rework, which saves both time and costs.

Supports Multitasking

Automation allows operators to manage multiple machines simultaneously or focus on other tasks while the CNC machine operates independently. This leads to a more efficient use of manpower, increasing overall factory productivity.

Reduces Operator Fatigue

Since the machine handles most of the physical and repetitive tasks, operators experience less fatigue. This not only improves worker satisfaction but also reduces errors caused by tiredness, which can lead to costly mistakes in manual operations.

Through automation, CNC hydraulic swing beam shearing machine provide faster, more efficient, and consistent production, lowering labor requirements and reducing operational costs. The result is a highly cost-effective manufacturing process that improves both the speed and accuracy of metal cutting operations.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى