What types of parts or products are typically manufactured using a CNC electric servo press brake machine?

2024-11-22

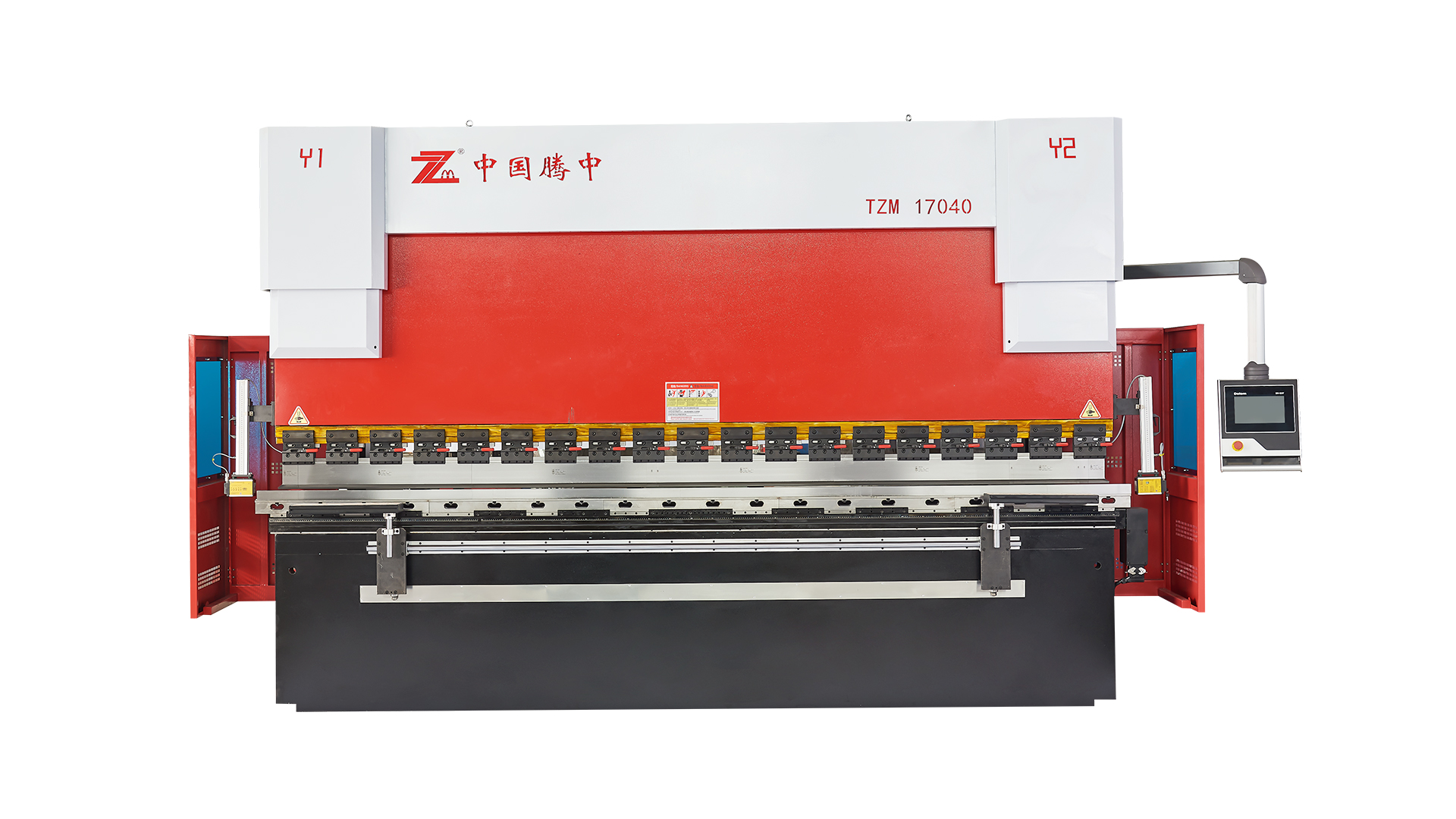

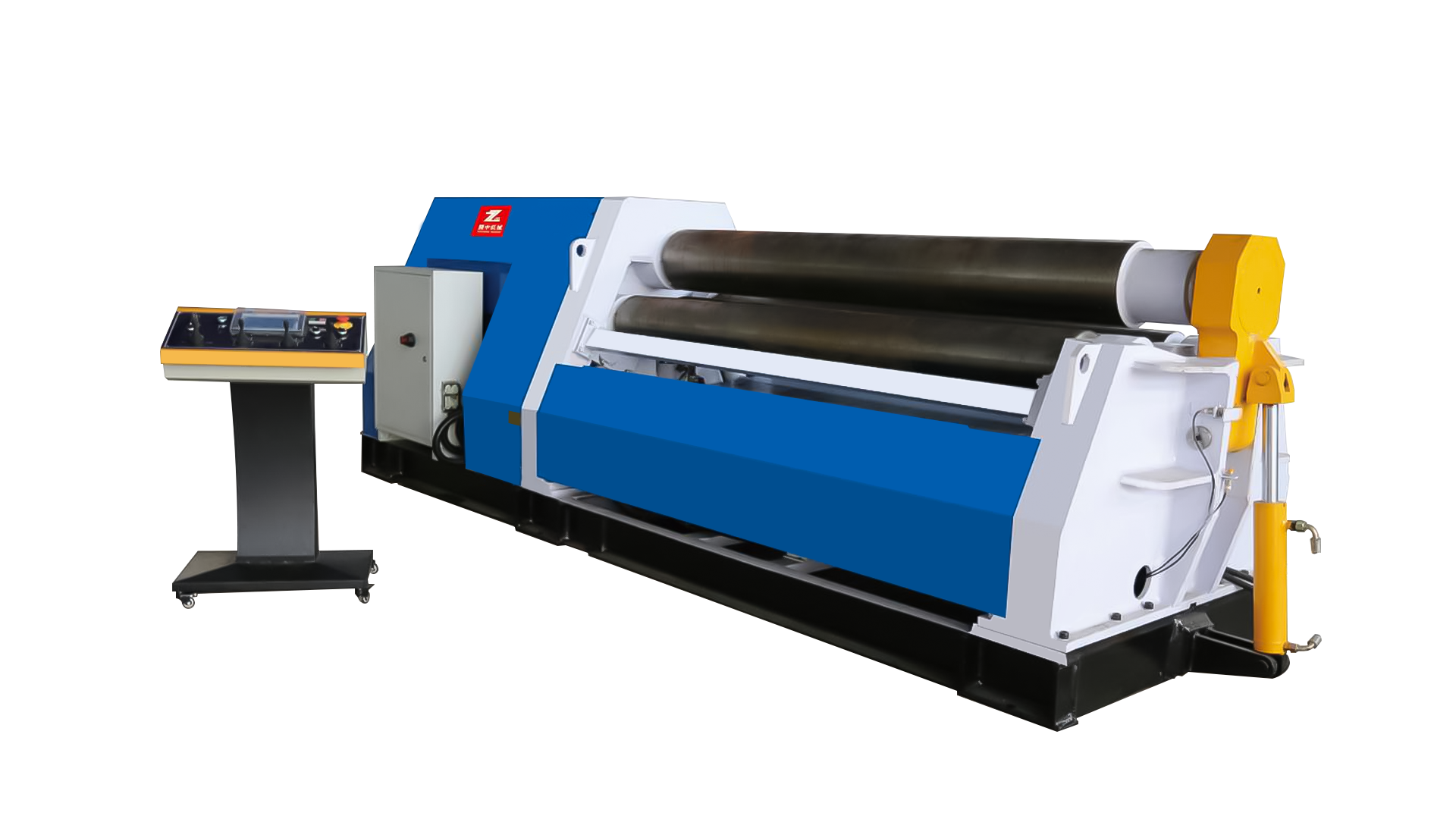

CNC electric servo press brake machine is versatile and widely used in sheet metal fabrication and various industries for bending and forming metal parts. Here are some common types of parts and products typically manufactured using these machines:

Automotive Components: Many parts used in the automotive industry, such as brackets, frames, and body panels, are produced using CNC press brakes. The precision and repeatability of CNC machines ensure that components fit together accurately.

Aerospace Parts: The aerospace sector requires high-precision components with stringent tolerances. Press brakes are used to form parts like fuselage sections, wing skins, and frames, where quality and accuracy are critical.

Industrial Equipment: Components for machinery and equipment, such as housings, enclosures, and structural supports, are often manufactured using CNC press brakes. These products may include bases, panels, and other structural elements.

Furniture and Fixtures: Metal furniture, including tables, chairs, and shelving units, often involves bent metal parts. CNC press brakes can produce stylish and functional designs with consistent quality.

Electrical Enclosures: Many electrical and electronic devices require protective enclosures. CNC press brakes are used to create these enclosures from sheet metal, ensuring that they meet safety standards and fit correctly.

HVAC Components: Heating, ventilation, and air conditioning (HVAC) systems use a variety of metal parts, including ductwork, brackets, and fittings. CNC press brakes help produce these components efficiently.

Architectural Elements: Architectural features like metal railings, decorative screens, and structural supports often require bending operations that are efficiently handled by CNC press brakes.

Signage: Metal signs and displays, including those with complex shapes or designs, can be manufactured using CNC press brakes, allowing for creative and customized solutions.

Custom Parts and Prototypes: Many manufacturers use CNC electric servo press brakes for custom applications or prototype development, where unique designs or specific specifications are required.

Safety Guards and Shields: Industries that require safety measures often use CNC press brakes to create protective guards, shields, and barriers to enhance workplace safety.

The precision and flexibility of CNC electric servo press brakes allow manufacturers to produce a wide range of products across different sectors, making them an essential tool in modern manufacturing processes.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى