How often should maintenance be performed on a ordinary CNC electric hydraulic servo press brake machine, and what does it typically involve?

2024-11-29

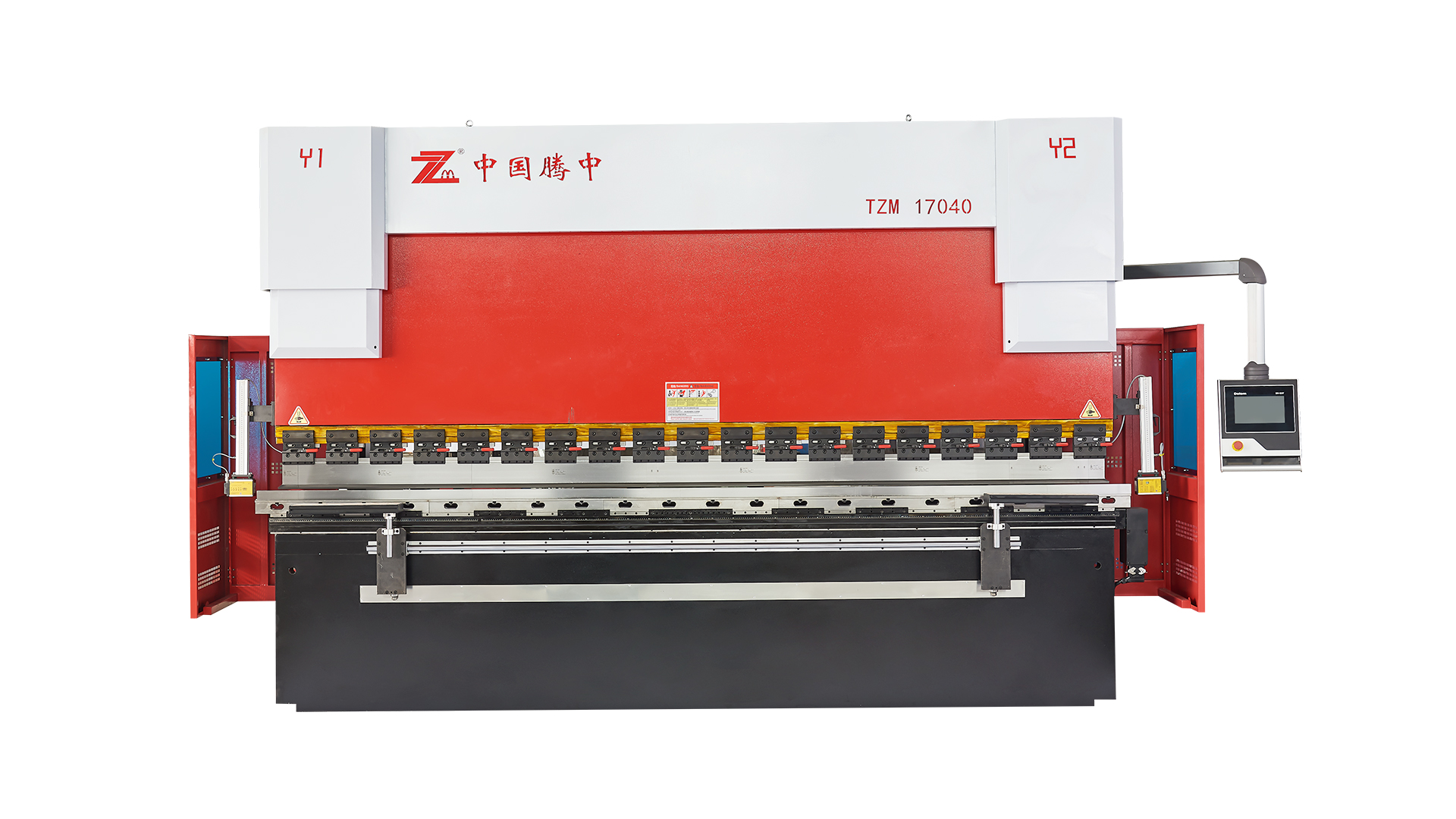

In the world of manufacturing, precision and efficiency are paramount. A ordinary CNC electric hydraulic servo press brake machine is a vital tool for bending metal sheets with accuracy. However, like any high-performance equipment, it requires regular maintenance to ensure optimal operation. So, how often should maintenance be performed on a CNC press brake, and what does it typically involve?

Maintenance Frequency

When it comes to the maintenance of a ordinary CNC electric hydraulic servo press brake machine, the frequency can vary based on several factors, including usage intensity and environmental conditions. Generally, a good rule of thumb is to perform maintenance checks every 500 hours of operation or at least once a month for machines in heavy use. For less frequently used equipment, quarterly checks might suffice.

Moreover, it’s crucial to incorporate daily visual inspections. Operators should look for any signs of wear, leaks, or unusual noises before commencing work. This proactive approach can help catch potential issues before they escalate, saving time and money down the line.

Typical Maintenance Tasks

The maintenance of a ordinary CNC electric hydraulic servo press brake machine typically involves a combination of routine checks and specific tasks. Here are some essential activities:

Hydraulic System Checks: Regularly inspect the hydraulic fluid levels and quality. Dirty or low fluid can lead to inefficient operation, so consider changing the hydraulic oil every 1,000 hours or as recommended by the manufacturer.

Calibration: CNC machines thrive on precision. Calibration should be performed regularly to ensure that the machine is bending materials to the correct angles and measurements. This involves checking the setup and making adjustments as necessary.

Cleaning: Keeping the machine clean is critical. Dust and debris can hinder performance, so routine cleaning of the work area and machine components is essential. Pay special attention to the bending tool and clamping surfaces.

A technician cleaning the CNC press brake

Electrical System Inspection: Since this is a CNC machine, the electrical components play a significant role in its operation. Regularly inspect wiring, connectors, and control panels for signs of wear or damage.

Lubrication: Ensure that all moving parts are adequately lubricated. This will help reduce friction and prolong the lifespan of the machine. Use manufacturer-recommended lubricants for best results.

The maintenance of a ordinary CNC electric hydraulic servo press brake machine is not just a routine task; it’s an investment in the longevity and efficiency of your equipment. Regular checks every 500 hours, daily visual inspections, and a thorough understanding of typical maintenance tasks can keep your press brake in top shape.

By staying proactive about maintenance, manufacturers can ensure that their press brakes operate smoothly, reduce downtime, and ultimately improve productivity. So, roll up your sleeves, grab that maintenance checklist, and give your press brake the love it deserves!

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى