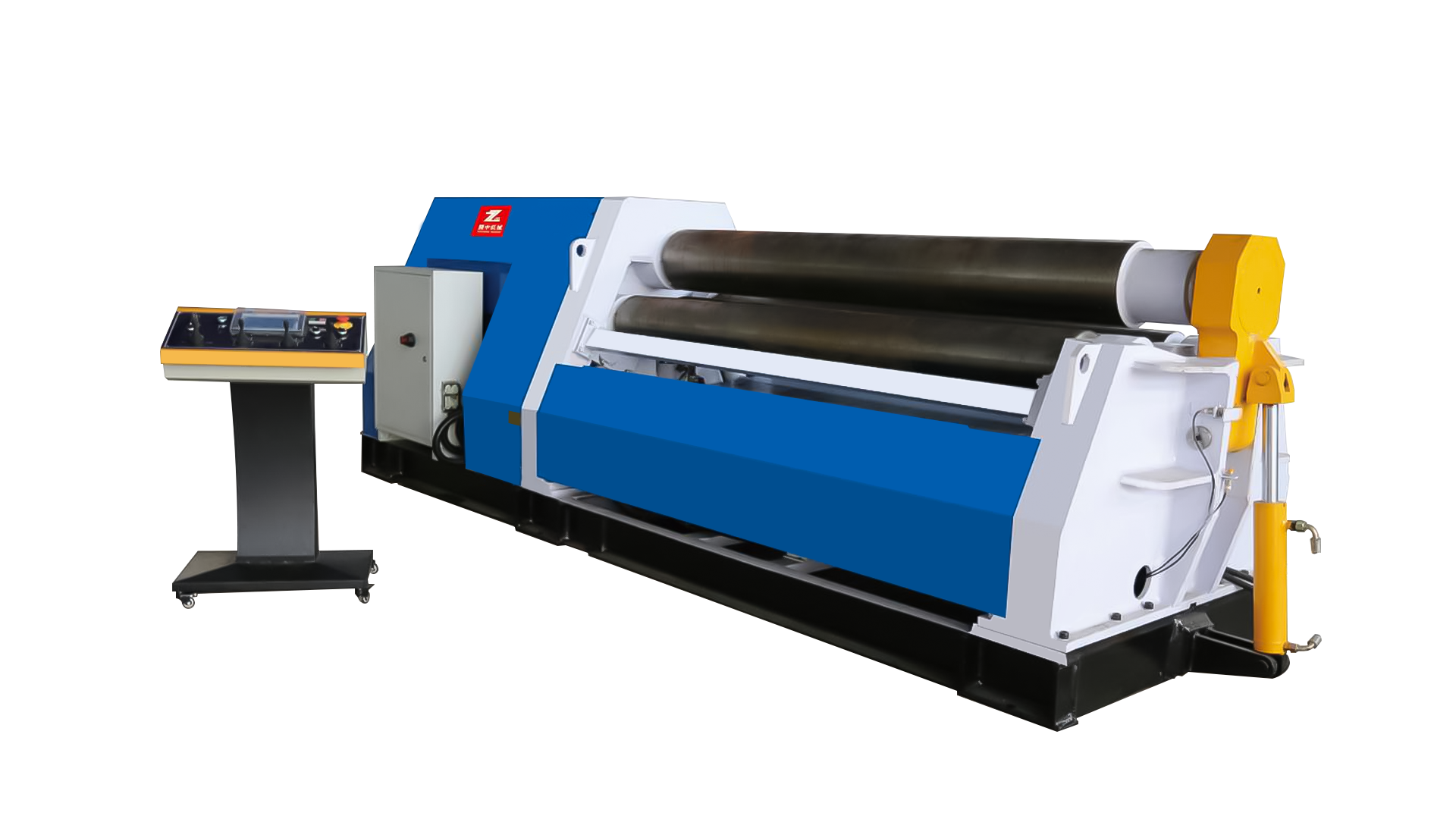

Upper roller material 45 # steel, medium frequency quenching, hardness HRC40 ~ 50. Solid forgings as a whole. The bearing body of the upper roll is an integral steel cast.

Lower roller material 45 # steel, medium frequency quenching, hardness HRC40 ~ 50. Solid forgings as a whole.

The main transmission device is located at the tail of the equipment and is composed of a main motor, a gear reducer with hard teeth, and an electro-hydraulic push lever brake. The reducer box is a welding box with a hard-tooth surface.

The auxiliary transmission device provides the lower pressure of the upper roll for the coil plate and is composed of the auxiliary motor, gear reduction box, worm gear, worm, screw rod, wire masterbatch, etc.

The frame is welded with a steel plate, the chassis is welded with channel steel, and the stress is removed by vibration aging after welding. The main connection position adopts a key and pin connection, which is convenient for maintenance and installation.

Lifting screw for integral forging.

Open gears are forgings.

The upper and lower roller switches are interlocked with the electric system. Electrical safety protection.

The main electrical components are Siemens. Equipped with fast hydraulic brakes.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى